13.06.2024

CNC metal processing is a specialized service that enables the processing of many materials using specialized software and numerically controlled machines. This process is largely automatic and follows a number of guidelines, depending on the parameters of the established algorithm. CNC is a particularly effective solution for metal details, which are in great demand in many different industries.

What is CNC metal processing based on?

CNC metalworking can involve many different activities, including turning, machining, milling, grinding and welding. Services in this area are provided by Karbo CNC specialists. In our company, we efficiently carry out all stages of work, including the development of a complete project, machine configuration, and development of the technological process, while maintaining quality control guidelines. Due to the use of technologically advanced tools and systems, we are able to effectively shape various metals. The result of our services is the processing of details that obtain the desired properties, target forms and optimal dimensional repeatability.

Professional design

At the initial stage of work, it is necessary to create an appropriate CAD/CAM project, which is created using a specialized program for developing models of target details. In this process, we ensure that strict technical parameters are maintained, including dimensions and geometry. The design is also directly adapted to the specifications of CNC machining machines and the properties of the metal itself, e.g. stainless steel or aluminum. The finished model therefore has features that will enable the processing of the material in terms of permissible size or thickness. After final refinement, the design is exported to a format compatible with the software of machines performing comprehensive CNC machining.

Machine configuration

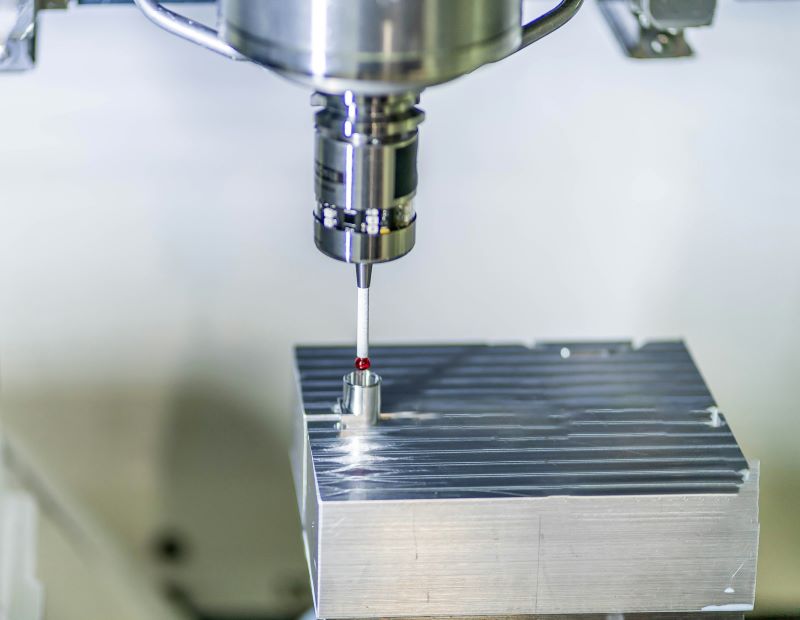

In order for the selected machine to perform efficient processing, it must be properly configured. An element processed using CNC technology requires appropriate mounting, necessary equipment and configuration of the required parameters. Depending on the type of work and the specificity of the implemented program, the machine executes the given instructions and carries out processing. In this process, specific movements and actions are performed, as a result of which it is possible to bring the material into the desired form. The correct course of all operations is supervised by a program that guarantees compliance with the target parameters.

What are the advantages of CNC metal processing?

CNC metal processing performed by our specialists is a comprehensive execution process that has many advantages. This service allows you to perform many different operations, depending on your needs and the type of tools used. This technology is suitable for a number of machining operations. At Karbo CNC, we are able to provide comprehensive service and at the same time have a personalized approach to each investor. We successfully implement even the most difficult projects, each time adapting the processing to individual requirements. Our company also offers other services, including 3D scanning and grinding.

Precision and repeatability

An important advantage of CNC machining is its high precision, which in practice allows for obtaining details with strictly repeatable parameters. This process automates many activities, which significantly reduces the likelihood of manufacturing errors and translates into increased quality of final products. CNC machining allows you to obtain many variants of the same detail, which only requires appropriate modification of the algorithm and changes to the machine settings. This technology also turns out to be exceptionally economical, as it significantly shortens production time and contributes to lower operating costs. In addition, high work safety should be added. Automation of the machining process limits direct contact of operators with machines, thereby reducing the risk of accidents at work.

Wide applications

The services of our Karbo CNC company are used in many industries, including pneumatic, automotive, aviation, medical, pharmaceutical, agricultural, energy, electronics and catering. The most frequently performed machining operations include CNC turning and CNC milling. Thanks to processing on a five-axis milling machine, the detail can be processed in all axes, including full simultaneous processing during one installation, ensuring correct execution in accordance with quality requirements. CNC turning is a processing that allows material to be reduced using appropriate cutting tools around the entire circumference of the element. Moreover, thanks to the use of driven tools with the option of working in the Y axis, it is possible to perform additional cutting operations during one clamping. We encourage you to contact our company by phone or e-mail and establish comprehensive cooperation.

18.06.2025

18.06.2025