24.01.2024

CNC milling is an extremely precise machining method that is based on the use of special numerically controlled devices. This process allows for the effective shaping of various materials, ensuring the possibility of obtaining almost any form. A significant advantage is very high milling accuracy, which cannot be achieved with traditional manual work. This service is aimed at obtaining an object with strictly defined parameters.

What are CNC metal milling services?

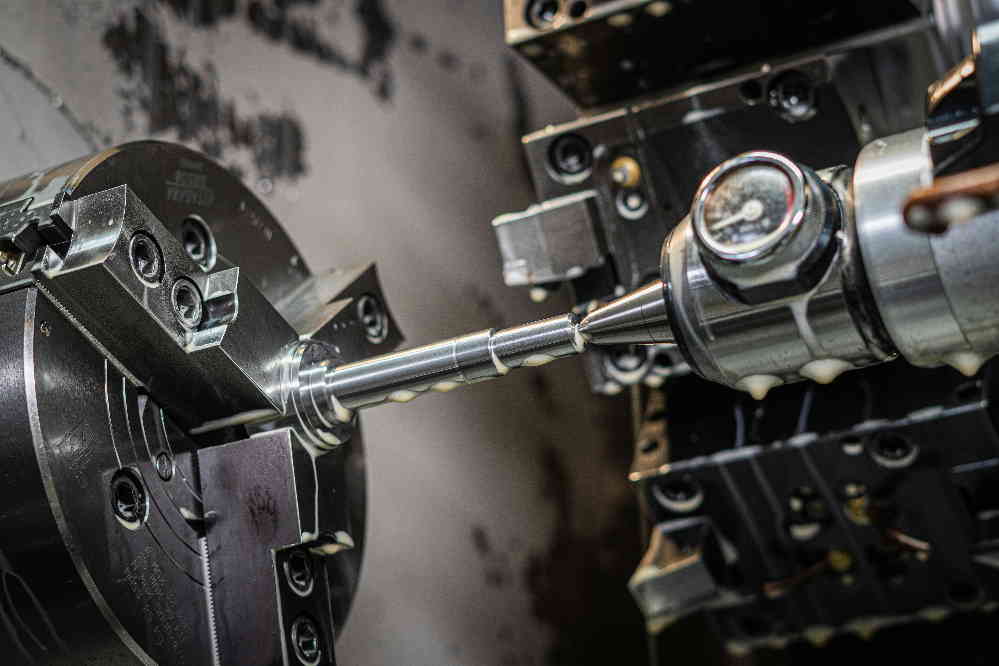

CNC metal milling services are among the most frequently performed machining activities. Our company Karbo CNC has prepared a comprehensive offer in this area, which also deals with turning, grinding and welding. Milling is a machining technique in which the workpiece is immobilized and the moving elements of the cutting tool are responsible for its processing.

Machining process

This service includes both individual, serial and mass processing. In each case, the process is very similar. A properly programmed CNC machine performs a specific number of repetitions to obtain the planned number of details. This process is based on the use of special computer software, which distinguishes it from manual processing. Once programmed, the machine performs all activities according to the requested commands. Setting positions and feeds, mounting the tool, selecting rotation speeds and other processing stages do not have to be controlled by the operator. This translates into increased precision of work, which ensures optimal accuracy and repeatability of details.

Numerical programming

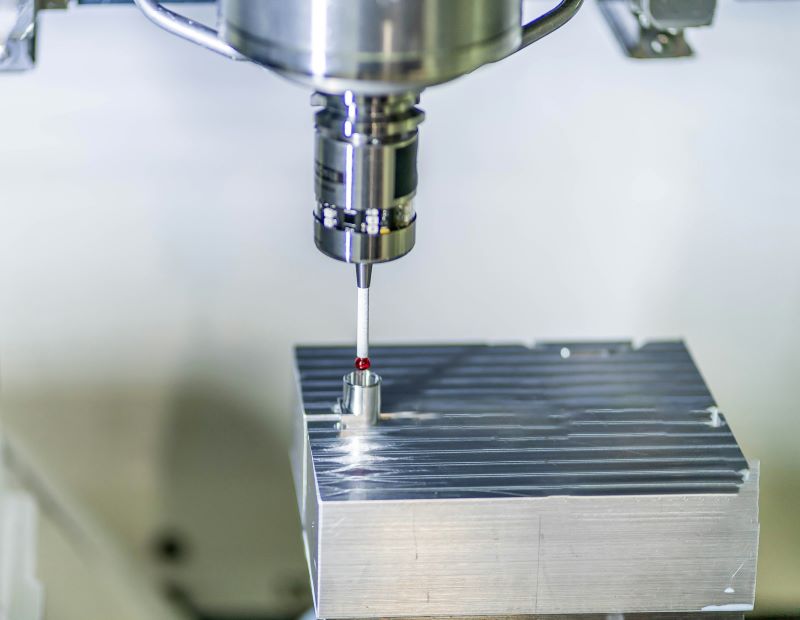

CNC stands for Computerized Numerical Control. In practice, this means that the milling machine used for processing is based on special algorithms and software functions. Commands from the program are saved in specially arranged blocks and then executed by the integrated machine controller. The machining process is fully automatic and does not require the intervention of the operator, who is only responsible for preparing the device, mounting the material and calling the appropriate program. In our company, we perform CNC milling in five axes, and each service is performed by creative, experienced and qualified professionals. We use innovative technological solutions and also deal with CAD/CAM design, which ensures comprehensive service – from design to the final product.

What are the uses of precision 3D CNC milling and what does the price of such processing depend on?

Precise 3D CNC milling is an innovative machining method, the price of which depends on several factors. This service allows you to create three-dimensional construction and architectural details that are widely used in many industries. The costs of its implementation depend mainly on the type and dimensions of the material being processed, the complexity of the project and the size of the entire order. The possible implementation of other CNC services is also important.

Advantages

3D processing allows for very detailed pattern processing and operation on several surfaces, which is important in the production process of various three-dimensional elements. This applies to various types of parts, forms and components that are used in many industries. The ability to process stainless steel, brass, aluminum, bronze, carbon, fiberglass, plastics and a number of other materials means that individual activities can be adapted to various needs in terms of many technical parameters. Our priority is always the highest quality of details, which translates into high customer satisfaction. Advanced technologies guarantee optimal accuracy and dimensional tolerance, and appropriate monitoring of individual processes contributes to maintaining the proper parameters of the processed surface.

Possibilities of use

Our company provides services for numerous segments. We offer machining for the automotive industry, including the production of spare parts for cars, gearboxes and engines. We provide comprehensive services for the machinery and pneumatics industries, preparing elements of machines, tools and industrial equipment. We also specialize in pharmacy and medicine, providing components for implants, prostheses and surgical tools. We also have a wide range of products for food processing, with particular emphasis on equipment for butcheries and slaughterhouses. We carry out CNC machining for the needs of electronics and energy, including the preparation of components for turbines, pumps, generators, radiators and housings. We encourage you to contact Karbo CNC and check our offer.

18.06.2025

18.06.2025