13.07.2024

CNC steel processing is a modern service that allows for the effective production, processing and shaping of various elements from many materials. This process is carried out using automated machines working based on advanced algorithms. CNC technology guarantees the implementation of the project with the desired precision and repeatability, which translates into high quality and full compliance with the guidelines. Comprehensive application in many industries is also important.

What is CNC steel processing?

CNC metal processing is currently one of the most popular services that are necessary in the context of processing stainless steel, aluminum and many other materials. Our company Karbo CNC has an extensive offer in this area, where we comprehensively deal with the entire process. The service includes the development of a CAD/CAM design, followed by appropriate configuration of the machines. Such processing can be performed in various forms, each time allowing for obtaining a high-quality detail. In our work, we use modern equipment, including advanced tools of high precision. Our processing always complies with the design assumptions in terms of form, dimensions and other parameters.

Professional design

In steel processing an important function is played by the CAD/CAM project, which is developed using advanced software. Element models prepared in this way may have specific technical parameters, including geometric form and size. The design must be compatible with the properties of the material being processed and the capabilities of the CNC machine used. The parameters of the equipment itself are also important, especially in terms of the maximum dimensions and permissible thickness of the metal object. Once completed, the design is exported to the appropriate format, which allows it to be read by steel processing algorithms.

Machine setup

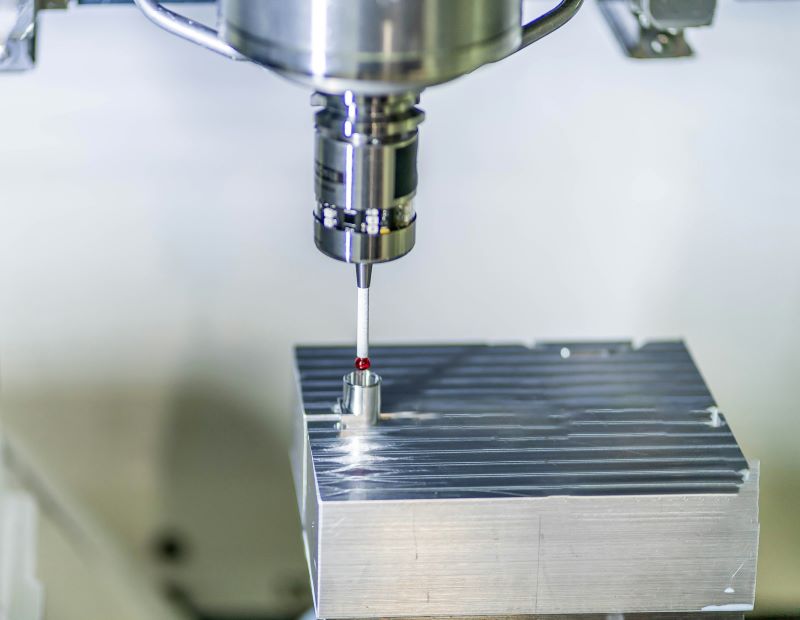

CNC machines performing processing must be properly configured before implementing the project. The element processed by processing must be secured in fixtures such as vices or spindles. The next stage is to adjust the operation of the equipment. After setting and configuring the machine, the CNC program is launched with the target processing instructions. The cutting equipment performs the required movements and activities, which allows for the final processing of the metal. The machine is constantly monitored, so there is no risk of errors during operation or lack of compliance with the guidelines included in the project.

What are the advantages of modern CNC steel processing services and more at Karbo CNC?

CNC steel processing services provided by our company can bring many benefits in numerous applications. In our company, we deal with comprehensive procedures such as milling, turning and grinding. We efficiently handle the entire steel processing process, which ensures professional service for each project. At Karbo CNC, we also offer 3D scanning and specialized welding services. We pay attention to the requirements of our clients, always advising the best means and technological solutions in the field of processing. We successfully carry out even the most unusual, difficult and demanding steel processing tasks.

Accuracy and effectiveness

The use of CNC technology guarantees effective processing of metal materials while ensuring high accuracy. Operations performed in this way are repeatable, which allows you to obtain many elements with identical physical characteristics. This method eliminates the risk of production errors, thanks to which the final products are of the highest quality. As part of processing, we can also prepare many different variants of the same detail, depending on the needs in terms of project parameters. CNC is a financially economical solution because it helps reduce operating costs and speed up production. Steel processing with this method remains extremely safe, due to the operator’s limited contact with the processing equipment and the reduced risk of accidents.

Versatile use

The treatments offered by our company are effective in many industries. We implement projects for the energy, electrical, automotive, aviation, pneumatic, catering, agricultural and pharmaceutical markets. Modern tools that we use during individual works allow for such versatile applications. We also perform CNC turning using cutting tools on the entire circumference of the component, which increases operational capabilities. We encourage you to check the Karbo CNC service offer and contact our experts.

18.06.2025

18.06.2025