13.01.2024

CNC turning is an innovative method of machining. This technique involves removing excess material from a selected element, which allows the processing of internal and external surfaces of objects with precisely defined geometry. The use of CNC technology has a positive effect on the precision and speed of machining, as it ensures fully automatic and accurate operation of the lathe cutter. This process can be successfully used in many industries.

What is CNC turning?

Turning on CNC machines is one of the services provided by our company Karbo CNC, in which we have prepared a comprehensive offer in the field of machining. We also specialize in milling and grinding details in accordance with the guidelines, ensuring high quality and precision. The machining process itself is largely based on the rotational movement of the workpiece and the straight feed movement of the machining tool. In our company, we successfully perform such machining using the point, circumferential or shape methods.

Modern processing

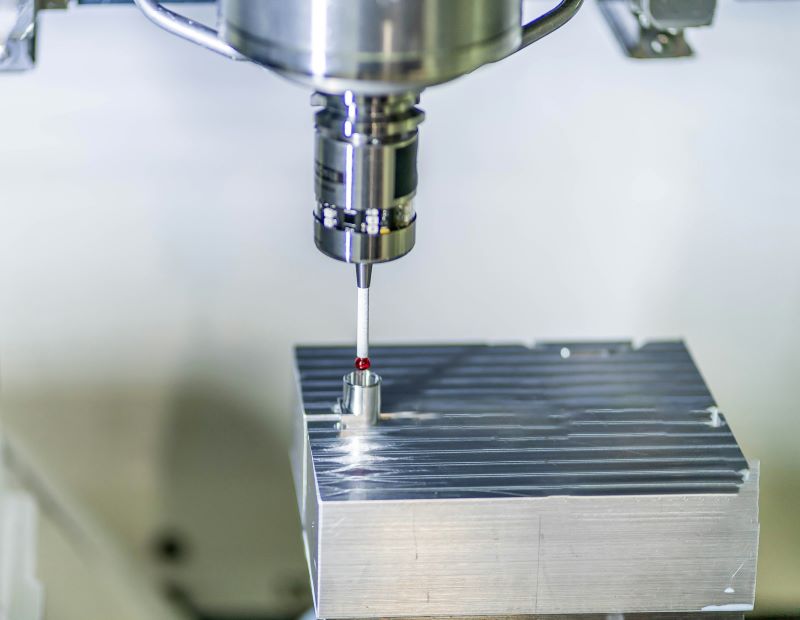

CNC machines used to provide our services differ significantly from traditional machining tools. The main difference is the method of controlling the elements responsible for processing the material. CNC (Computerized Numerical Control) involves the use of special software that allows machining to be performed based on appropriate functions and algorithms. The program is written in a fixed block system and then executed by the controller. The process itself takes place without the participation of the operator, who is only responsible for carrying out the initial configuration. At Karbo CNC, all activities are performed by experienced professionals with a creative approach who use modern technologies. We also create CAD/CAM designs, thanks to which we comprehensively perform each task until a satisfactory final product is obtained.

Principle of operation

We can process various elements using this method, but in each case the whole process looks quite similar. The CNC machine is programmed to perform a specific number of repetitions to enable the planned work to be completed. The object placed in the lathe is set into rotation, and the lathe knife in linear motion cuts the outer layer of the material in accordance with the set parameters of the machine. The computer software used for this purpose makes CNC machining significantly different from the standard manual method. The lathe efficiently performs all tasks in accordance with the instructions, which eliminates the need to manually mount and set the knife or correct subsequent stages of work. The method we offer guarantees very high precision and repeatability, thanks to which the finished details successfully meet all parameter requirements.

What is CNC thread turning and what does the price of this service depend on?

CNC thread turning is currently one of the most common applications of such machining, and its price as a service depends on several key aspects. Costs are influenced primarily by the type of material processed, its size, the scope of the entire order, the complexity of the project and the need to provide additional services. Turning itself allows for the production of various internal and external threads in rotating workpieces. Their preparation requires multi-stage work of the cutting lathe knife, which with each subsequent pass deeper and deeper into the material and finally creates a thread outline.

Comprehensive application

Our company specializes in professional CNC machining for many different business segments. We optimally adjust the turning method and form to the customer’s guidelines, thanks to which the selected solutions optimally meet all the required parameters. We successfully perform operations on numerous materials, such as stainless steel, aluminum, fiberglass, bronze, brass and plastics. We process elements for the automotive industry, for example to prepare replacement components for cars, engines and gearboxes. We specialize in pneumatics and the machinery industry, processing parts of various devices, machines and tools. We also serve the food processing industry, including the processing of slaughterhouse and butcher shop equipment components. We offer services for the energy and electronics segment, preparing components for generators, housings, pumps, turbines and radiators. We encourage you to check our offer and contact Karbo CNC specialists.

18.06.2025

18.06.2025