13.02.2024

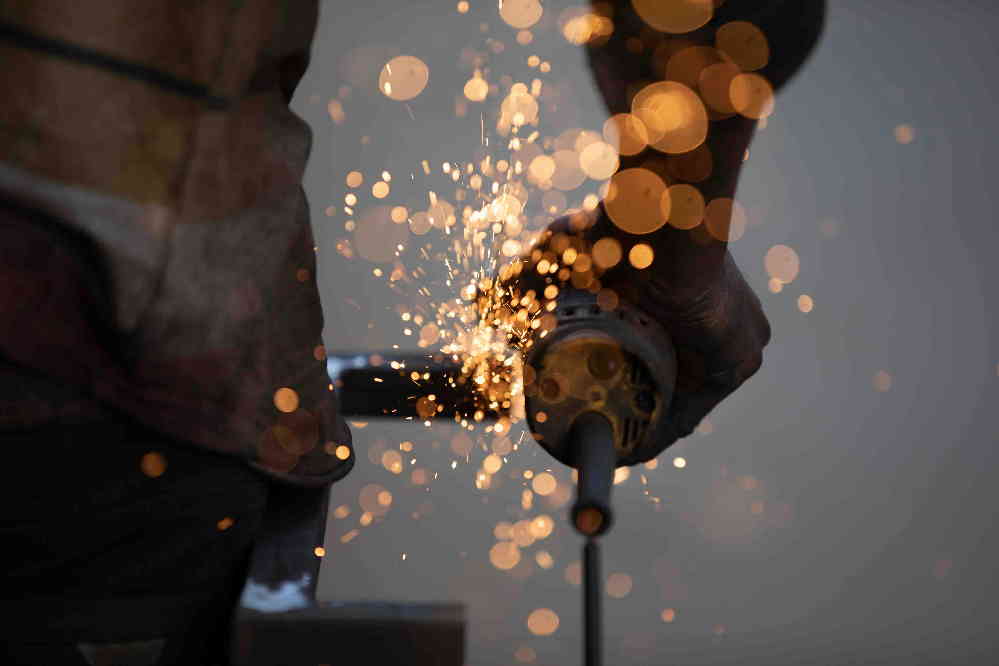

Grinding stainless steel is one of the most frequently used methods of processing this metal, which is used in many industries. This treatment involves mechanical improvement of the protective properties of the material. Its implementation allows to increase the strength of finished stainless steel details, and at the same time increases their visual attractiveness and extends their service life.

What is stainless steel grinding?

Grinding stainless steel is one of the basic services provided by our company Karbo CNC, which is an industry leader in the field of mechanical processing. This procedure involves the use of special abrasive tools. Stainless steel is self-passive and contains alloying elements on its surface that create a protective layer with anti-corrosion properties. In order not to lose them as a result of mechanical processing, we carry out abrasive processes using tools made of appropriate fibers.

Processing methods

The most popular grinding techniques for stainless steel include the use of flap wheels, fiber wheels, endless belts and grinding fabrics. If the first method is used, flexible grinding discs can be optimally adjusted in terms of dimensions and grain size to the specific work being undertaken. The flexibility of the discs allows them to easily reach welds, joints, bends and other hard-to-reach places. In the case of fiber grinding wheels, thin sheets of sandpaper are used. Endless belts are used as an element of the equipment of stationary grinding machines, the drive mechanism of which enables optimal adjustment of the abrasive to the shape of the processed element. The technique using non-woven fabrics requires the use of a synthetic backing to which abrasive particles are evenly attached. This method combines the high deformability of the grinding disc with its high resistance, which reduces the risk of damage to the steel surface.

Appropriate tools

Grinding is a demanding and complex process that must be carried out using appropriate tools. Depending on the purpose of processing and the specific nature of the work, angle, oscillating, eccentric, belt or delta grinders are used. The selection of the appropriate solution depends largely on the size of the surface to be treated. The use of the right abrasive material is also important. In the case of stainless steel, it must not contain sulfur, chlorine or iron. For this reason, the optimal solution is to use synthetic abrasive materials that are free of particles that increase the risk of intergranular corrosion. For processing, we can use, for example, aluminum oxide, i.e. corundum.

What are the uses of grinding stainless steel?

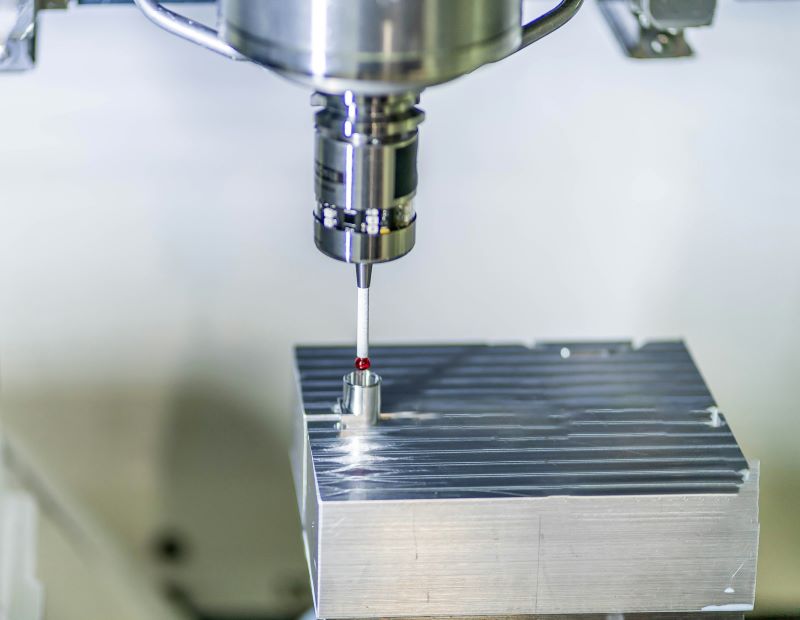

Grinding stainless steel requires great care during processing, because any manufacturing errors may lead to damage to the material. This, in turn, increases the risk of increasing surface roughness, and thus susceptibility to the deposition of contaminants and potential corrosion. In our company, we also efficiently carry out other processes, including milling, turning, 3D scanning, CAD/CAM design and welding services. In addition to stainless steel, we also process aluminum, brass, bronze, plastics, glass fibers, carbon and other colored materials.

Benefits

In our company, we use innovative CNC machining methods, which provide enormous possibilities of shaping stainless steel. The great advantage of this technique is the guarantee of high precision, which translates into repeatability of parameters in the case of serial work. Computer control additionally eliminates the risk of manufacturing errors, thanks to which the finished details are of high final quality. CNC grinding also gives us the opportunity to work on the same components in different variants, which is done by appropriate modification of the program. The economics of this solution are also important, as it shortens processing time and costs. We perform work in safe and properly prepared conditions.

Possibilities of use

Grinding is a very popular process, which is why it is used in many segments. This service is useful at the stage of production of various parts for the automotive, machinery and pneumatic industries. CNC machining is increasingly appreciated in the pharmaceutical, medical and food processing industries. Stainless steel details treated in this way are also used for the energy, electronics and aviation industries. We encourage you to contact our company Karbo CNC and check out our other services.

18.06.2025

18.06.2025