31.03.2025

Milling holes is one of the most commonly used methods of machining various details. This process is carried out using technologies that allow for the efficient processing of many materials. Thanks to this method, holes of variable diameter and cross-section can be made, including not necessarily round ones. Milling in this form is used in many industries, which results from high precision, repeatability and freedom in shaping the obtained forms.

How is CNC hole milling in metal done?

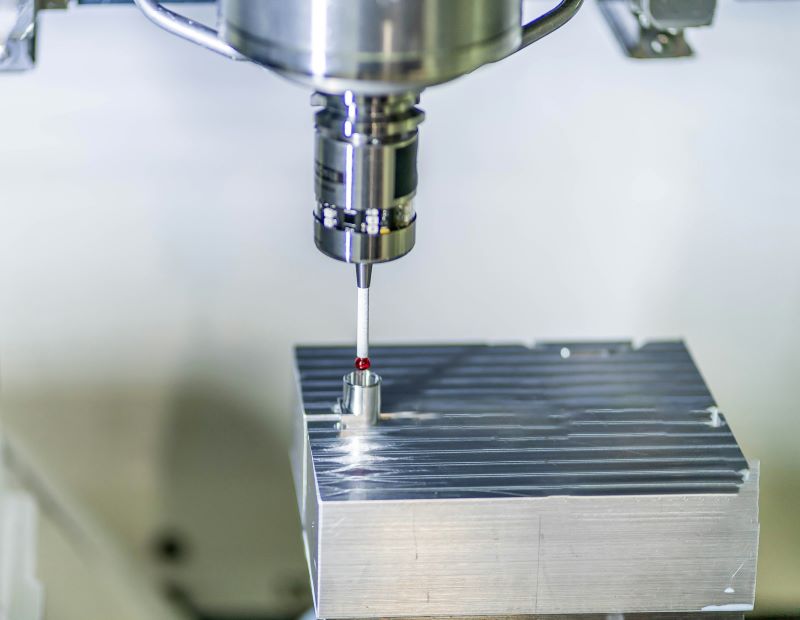

CNC hole milling in metal involves the use of numerically controlled machines in the machining process. This service is performed by specialists from our company Karbo CNC, where you can always count on comprehensive service. This type of milling allows you to remove part of the material by making an appropriate recess in it, which is intended to give the detail specific geometric features. A specialized CNC milling machine is used in this process.

In our company, we perform machining in both larger and smaller production series, which allows for an individual approach and great flexibility.

Comprehensive process

The process of creating holes using this method is multi-stage. At the beginning, we carefully analyze all the customer’s requirements to select the most optimal processing technologies and develop an appropriate action plan. The basis is the preparation of technical documentation specifying the exact parameters of the target hole.

We always carry out milling in accordance with established guidelines and assumptions. At the end, a comprehensive executive control is carried out, based on an advanced quality assurance system. CNC machines are properly configured, and the selected program guarantees high precision of work.

The milling machine can be adjusted in terms of position, feeds or rotations of the tool, which operates based on complex functions and algorithms. The controller integrated with the machine efficiently executes all commands. Manual operation is significantly limited – it comes down to securing the material, arming the milling machine and starting the program, which translates into greater production efficiency.

Versatile application

Currently, drilling is considered the more traditional method of making holes. However, this solution does not always work well when machining some materials, which is due to the difficult breaking and removal of chips. Milling is more versatile in this respect.

This method can be used to make holes of various sizes, including blind holes with a flat bottom and holes in thin-walled parts. Milling is irreplaceable in the process of preparing various forms and dies that require precise recesses, recesses or pockets.

This method also works great for developing threads that are later used as durable screw connections. We can make holes in various types of architectural, building or construction details. Our previous projects can be checked on the Karbo CNC website.

Why is it worth entrusting us with milling holes in steel?

Milling holes in steel is an exceptionally effective and at the same time economical service. The costs of this type of processing depend on the dimensions and other parameters of the detail, as well as the level of complexity of the project. The size of the entire order is also an important issue.

The use of CNC machines provides significant savings compared to more traditional solutions. Our specialists can provide a free quote, which is an additional advantage.

In addition to steel, we also offer processing of aluminum, brass and non-ferrous metals.

Service benefits

Milling performed by our company provides huge possibilities for material processing, enabling trouble-free work even on several surfaces at the same time. In the case of each order, we take care of the highest quality of workmanship and ideal dimensional tolerance.

The same applies to other services provided by Karbo CNC, including:

– turning,

– grinding,

– welding,

– 3D printing and scanning,

– CAD design,

– comprehensive locksmithing.

All activities are constantly monitored and supervised, which minimizes the risk of losing the desired material properties and the occurrence of any surface defects.

Professional service

In our company, experienced specialists who have the appropriate qualifications and regularly participate in training are responsible for milling services. At Karbo CNC, we approach each project individually, ensuring compliance with standards and work safety. Our specialists are happy to undertake even the most unusual, demanding and complicated tasks. Their implementation is significantly facilitated by our extensive machinery park. In case of any questions, we encourage you to contact us by phone or via the form on the website.

CNC hole milling is a modern, precise and effective machining method that is used in many industries. Thanks to advanced technology and qualified staff, Karbo CNC ensures the highest quality of services, regardless of the scale and complexity of the project.

We invite you to cooperate!

18.06.2025

18.06.2025