14.05.2025

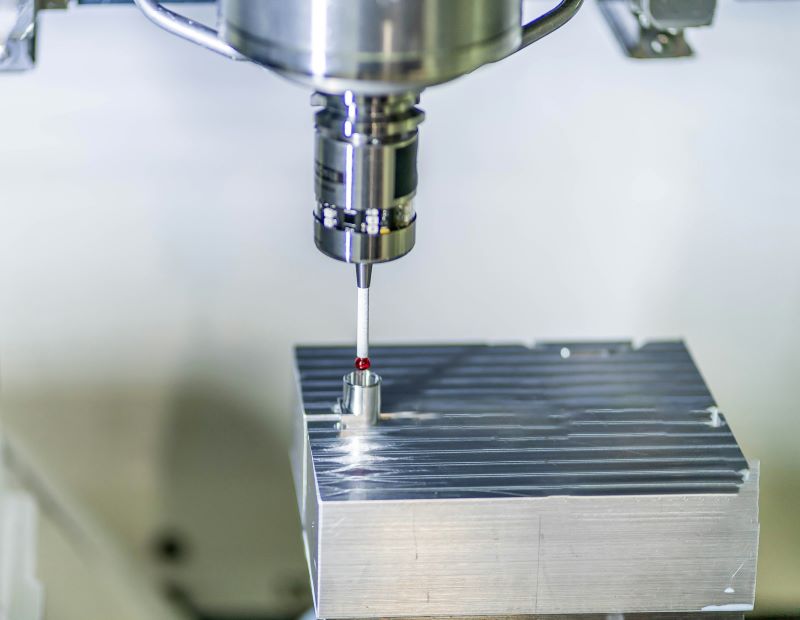

Plastics processing is an indispensable method for processing, shaping, and finishing various synthetic materials. Currently, this type of work commonly utilizes CNC technology, i.e., numerically controlled machines. This solution provides extensive processing options while guaranteeing compliance with all design parameters. Plastics are processed primarily to impart specific dimensions, shapes, properties, and other characteristics to components. CNC technology allows for the rapid completion of both individual and serial orders.

What is plastics processing?

Plastics processing can be based on various processing methods, most commonly milling, turning, or grinding. Our company, Karbo CNC, provides these services, utilizing efficient and precise technological solutions. We successfully process synthetic materials, taking into account their specific parameters, such as flexibility, melting point, and chemical resistance. At Karbo CNC, we process polycarbonate, polypropylene, polyethylene, and other technical plastics.

Comprehensive scope of services

Numerically controlled machines are based on technology that works exceptionally well with plastics. CNC machining can be used on a wide variety of materials. We process polycarbonate, polypropylene, and polyethylene, for example. Numerically controlled machines ensure high-quality parts, as well as complete repeatability and dimensional accuracy. Our services include preparing a custom CAD/CAM project, which includes a digital model of the target component. At Karbo CNC, we place particular emphasis on meeting all customer needs in terms of technical specifications. We also handle machine configuration, and the machining process itself is largely automated. We plan each order individually, adapting machine parameters to the properties of the specific material.

Advanced Technological Process

Machining synthetic materials using CNC machines is carried out using a technological process that faithfully reproduces the target dimensions and shapes of the components. Individual plastics vary in strength, flexibility, hardness, and other parameters, so all work must be carefully planned. The material to be processed is mounted in a CNC machine, which requires appropriate configuration. A pre-prepared program allows for efficient execution of work according to a pre-defined algorithm, read by a special controller. At our company, we ensure constant control of the entire process, allowing us to process and shape plastics without fear of errors or other irregularities. This approach ensures repeatability and high-quality details in every batch.

Why is CNC plastic processing a good choice?

CNC plastic processing is an exceptionally versatile service that can streamline many production processes. Choosing it offers a number of benefits, especially when working with our experts. At Karbo CNC, we provide comprehensive services that cover all processing stages and eliminate the need to hire additional subcontractors. We also successfully provide other professional services, such as 3D scanning and printing. We are familiar with specialized tools and technologies, so we can take on even the most challenging and unusual projects. CNC technology enables fast order fulfillment, cost-effective material processing, and reduced risk of errors.

Accuracy, Economy, and Safety

The machining of synthetic materials using numerically controlled machines is highly accurate, resulting in high precision of the finished products. Each product manufactured using this method is characterized by perfectly reproduced physical parameters, allowing us to successfully prepare fully repeatable product series. CNC machines also allow for changes to the implemented algorithms, which in turn enables the production of different variants of the same component. We can also process plastics very economically. The services provided by our company reduce work time and therefore financial outlays. As a result, production is faster and less expensive. The reduced risk of accidents is also noteworthy, as all operations are carried out in compliance with the highest safety standards.

Universal Applications in Many Industries

Plastics are used in many industries, which translates into the high popularity of our machining services in various fields. We perform CNC work for the electrical, energy, agricultural, pneumatic, pharmaceutical, automotive, and aerospace sectors, among others. We have modern machinery at our disposal, allowing us to handle both small and large production runs, always ensuring consistent performance. We also ensure the skills of our specialists, who participate in ongoing training. We provide free quotes and expert advice on CNC plastic machining. We invite you to explore our services and contact Karbo CNC by phone or via the form.

18.06.2025

18.06.2025