07.05.2025

Stainless steel machining can be performed in a variety of ways, finding wide application in many projects. Modern CNC machines are currently used for this technological process. Stainless steel's corrosion resistance makes it highly practical and versatile. Machining it using CNC machines ensures high precision and repeatability, while also minimizing material waste.

How is stainless steel machining performed?

Stainless steel machining is a service you can entrust to the experts at Karbo CNC. We perform precision CNC turning, CNC milling, welding, and detail finishing. We work based on CAD/CAM designs, which we prepare according to the client’s requirements. We then configure the CNC machines and carry out the cutting process according to the program’s algorithm.

Stainless steel is characterized by excellent corrosion resistance and low thermal conductivity. However, this material can be quite demanding to process, so it’s worth trusting the specialists. At Karbo CNC, we handle the entire process – from design preparation, through machine setup, to quality control and final detail finishing.

Using the Right Tools

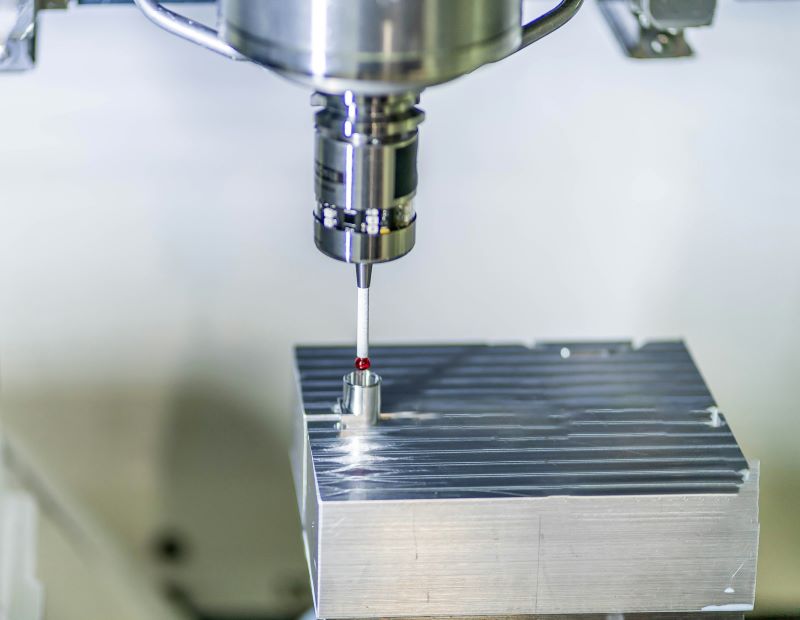

Stainless steel is characterized by high abrasion resistance and overall durability. Therefore, its processing requires the use of tools that can effectively shape this material. At Karbo CNC, we use modern, high-temperature-resistant tools equipped with protective coatings that reduce friction and the risk of material sticking. Our machines are equipped with cooling systems, which extend tool life and reduce the risk of thermal deformation. Protective tool coatings significantly reduce friction and the risk of steel sticking. We successfully perform complex and demanding services, including machining very large batches of components. Our technological process is optimized because we carefully select the depth, rotational speed, feed, and other machine parameters to suit the specific project.

Numerically Controlled Machines

Numerically controlled machines are ideal for processing stainless steel. CNC machining performed by our company can encompass even the most complex technological processes, while guaranteeing the required precision. Their effectiveness is largely determined by the use of appropriate CAD/CAM software, which allows us to prepare an accurate digital model of the planned part. Numerically controlled machines operate according to a pre-defined algorithm and are constantly monitored. All of our stainless steel components are subject to strict quality control, allowing us to make necessary adjustments on an ongoing basis. CNC technology also contributes to reduced material and energy consumption and accelerates the machining cycle.

Where is CNC machining of stainless steel used?

CNC machining of stainless steel is currently a very common service, widely used in numerous industries. We process this material for businesses that prioritize quality, including the automotive, aerospace, electronics, energy, agricultural, pneumatics, and pharmaceutical industries. Depending on the client’s requirements, we can comprehensively customize and personalize the entire machining process. We also guarantee high-quality services for other services, such as 3D scanning and printing.

Precision, Automation, and Cost-Effectiveness

Numerically controlled machines ensure very high precision in stainless steel processing. Due to the extreme precision in machining this material, we are able to obtain parts and components with highly repeatable technical parameters. The use of CNC technology also allows for significant automation of the entire process, which in turn reduces the risk of errors. The improved quality of the final product and the ability to create a given part in several versions, depending on the program and algorithm settings, are also significant. The high cost-effectiveness of our services is also noteworthy. CNC machining contributes to shorter work times and lower production costs. This is further enhanced by the safety provided by limited operator contact with cutting tools.

Comprehensive Services

Stainless steel can be shaped in many ways. CNC turning is a highly versatile solution, allowing for a wide range of machining options when used on the entire circumference of the workpiece. We also cut steel using CNC milling, which allows for exceptionally diverse cuts on a variety of surfaces. We also offer welding of stainless steel components, as well as 3D scanning and printing. We provide free quotes and expert advice on choosing the right technology. We encourage you to contact us by phone or via the form, and we invite you to learn more about Karbo CNC’s range of services.

18.06.2025

18.06.2025