04.06.2025

Steel milling is a very common method for machining this material. The entire process relies on the use of specially selected cutting tools, which translates into a wide range of shaping possibilities. Steel is a metal processed using numerically controlled machines, ensuring accuracy, repeatability, and design freedom. The use of modern CNC milling machines allows for results often unattainable with other solutions. At Karbo CNC, we mill both standard and stainless steel for companies across Poland, ensuring high quality and full technical support.

How is CNC milling of steel performed?

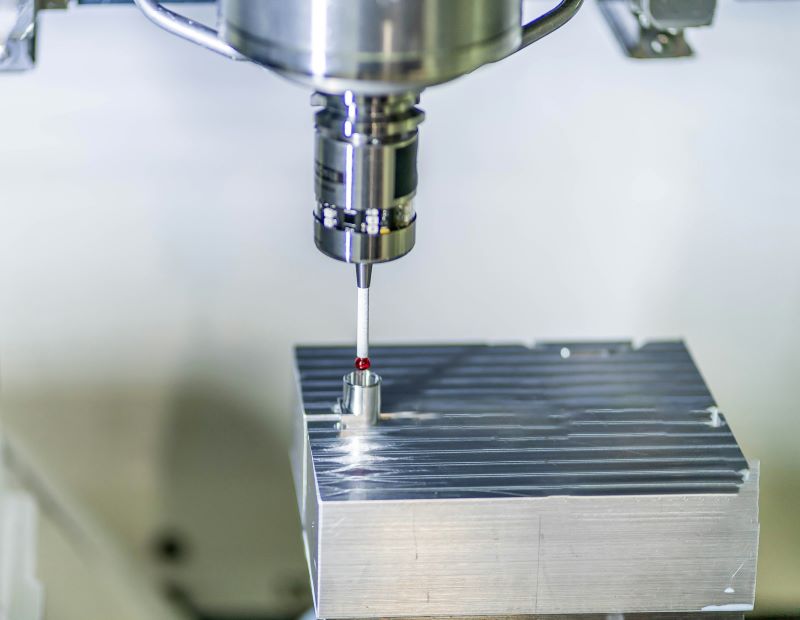

CNC milling of steel is performed by experienced specialists at our company, Karbo CNC, where you can count on exceptionally professional service. We also successfully perform turning of this material and provide other services such as welding and grinding. The milling process is performed by clamping and fixing the component, then shaping it using an integrated cutting tool. The CNC milling machine is set in rotation relative to the workpiece, which occurs according to a pre-defined program. This technology allows for the production of both small and very large production runs. We approach all tasks professionally to best meet the needs of our customers. Milling is performed fully in accordance with a prepared computer program, ensuring high accuracy, repeatability, and flexibility in producing various shapes and sizes.

Professional and specialized machining

CNC milling is a process carried out based on the appropriate machine configuration, which translates into an optimal number of operational repetitions. As a result, we can always deliver the required number of finished parts. The milling machine performs tasks based on a previously developed program, which allows for the execution of each operation according to the instructions. This process includes the selection of specific positions, rotations, and feeds, as well as the proper tool mounting. The work is performed with high precision, which translates into the appropriate technical parameters of the components. CNC milling machines operate based on specific functions and algorithms, allowing commands from the program to be efficiently executed by the controller integrated with the machine. This machining is largely automated and limits the operator’s involvement; the operator only needs to set up the equipment and clamp the material. Once the program is launched, we can work simultaneously on several axes. The milling process at Karbo CNC includes design analysis, selection of tools and cutting parameters, machine programming, milling machine setup, and machining execution – the operator only controls the workflow, minimizing the risk of errors.

Comprehensive technological process

Milling is a service performed in stages. The basis for implementation is a thorough discussion of the project requirements, which determine the selection of appropriate technological solutions. At this stage, developing appropriate documentation is crucial, as well as properly planning the entire machining process and selecting the best tools. Regular or stainless steel must always be shaped in compliance with certain rules due to comprehensive quality assurance controls. Our company offers three-dimensional milling, which allows for the creation of three-dimensional architectural, construction, and structural details. We also offer 3D milling for the production of architectural and structural elements. You can find examples of Karbo CNC projects on our website.

Why should you entrust your stainless steel milling to an experienced company?

Stainless steel milling is a service that requires appropriate knowledge and experience. It’s worth entrusting this type of machining to our specialists, as we always approach each project individually. At Karbo CNC, we ensure compliance with applicable quality standards and place particular emphasis on production safety. We successfully undertake challenging and unique tasks, which is also due to the availability of modern machinery. We have experience working with various grades of stainless steel, selecting tools and parameters to achieve ideal surface quality, minimal tool wear, and repeatability even in complex projects.

Wide Range of Applications

A significant advantage of CNC milling is its high versatility. This technology enables the processing of not only steel and stainless steel, but also brass, aluminum, and various non-ferrous metals. At Karbo CNC, we also manufacture plastic components. We use CNC milling machines to produce components, parts, and elements of various shapes, which are needed by numerous industries. We serve, among others, the industrial, construction, automotive, energy, and aerospace sectors. Steel itself is an exceptionally versatile material for machining, allowing us to effectively meet all technical specifications. We ensure high dimensional tolerances and excellent quality of every detail. We continuously monitor and supervise the CNC machining process to ensure impeccable surface properties of each product.

Economical and Efficient Implementation

Steel machining using CNC machines is an exceptionally cost-effective service. At our company, the cost of milling this material depends primarily on its specific nature and the target dimensions of the parts, as well as the size of the entire order. We also consider the complexity of the project. Costs also depend on the type of material and the quantity ordered. However, due to the exceptionally fast and efficient implementation, choosing this solution can contribute to significant savings during the production phase. We offer individual pricing and a free technological consultation. We encourage you to contact Karbo CNC and learn more about our machining services.

18.06.2025

18.06.2025