CAD design is an extremely important stage in the production process of various elements, components and parts used in many industries. This service involves the use of specialized hardware and software for digital geometric modeling.

It allows you to prepare a record of the construction of various objects, as well as their entire systems. Such a design includes all geometric, dynamic and material features of the product, constituting the full construction documentation.

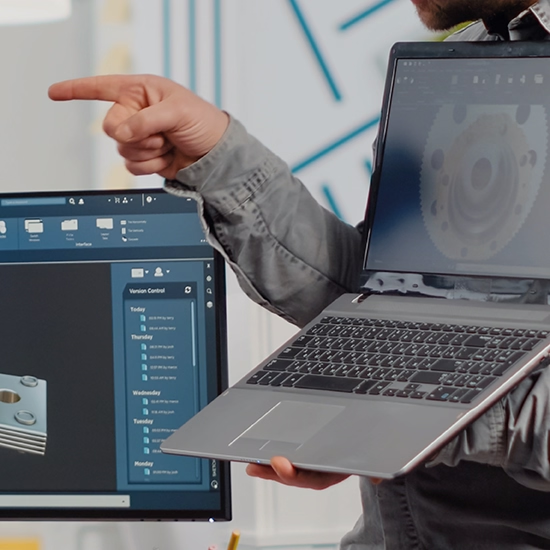

CAD design is a service that we successfully provide at our company Karbo CNC. It covers a number of different activities. The basis is a computer representation of the planned structure, including digital modeling by creating a product mock-up and detailed documentation.

Important stages of work include managing databases containing, for example, information about standardized elements or material properties. Design may also include simulation and visualization of the planned product.

CAD combines various areas of engineering activities. Designing with this method aims to optimize the structure and its production processes, which is done through various tests and analyses. CAD allows you to perform strength calculations, scan structures and shapes of objects for reverse engineering, and process the resulting digital models based on them. The whole process is similar in most cases.

The basis is the development of a general concept of the target object, which is often accompanied by 3D scanning of a previously prepared mock-up of the product. In the next stages, digital models of the main elements and other parts are created. An important process in creating a CAD design is carrying out strength calculations, including collision analysis. We select materials for individual components and evaluate them in terms of ergonomics and visual aspects.

After preliminary work, a prototype of the planned facility is made. CAD technology allows for the effective introduction of potential changes and corrections, as well as the estimation of project implementation costs. An important activity is the preparation of documentation, including, for example, test reports and installation and operating instructions.

At further stages, instructions for CNC machines that are used in the production and processing of products are also developed. Finally, it is also possible to prepare the final presentation of the product for its final visualization. At Karbo CNC, we prepare projects of this type for the needs of many industries. They work successfully in machine engineering, the automotive sector, construction and architecture, electrical engineering, and even in the arms, medicine and pharmaceutical industries.

CAD design is one of the most specialized services provided by our specialists.

We have extensive technical knowledge and good knowledge of legal regulations, directives in force in many industries and normative studies.

We work effectively on various CAD projects using advanced software.

We have many years of experience and proficiency in operating many programming environments, which guarantees careful development of product parameters and its technical documentation.

Evaluate customer requirements, select appropriate processing methods and technologies, and develop a work plan.

Creation of technical and process documentation, and preparation of appropriate tools and selection of machinery.

Execution of the planned technological process, according to the guidelines and documentation.

Conduct quality control, based on the established quality assurance system.

At Karbo CNC, we provide full computer-aided design. We comprehensively analyze the market and the client’s business needs to match the best solutions. We not only prepare CAD designs, but also carefully plan and carry out serial production. We also provide support throughout the entire service process, which translates into greater investor awareness of the technologies used.

Advanced design tools allow us to create highly refined models, as well as prototypes and visualizations showing the actual features of the finished product. We use modern technologies that guarantee optimal selection of parameters and predict the product’s reaction to various operating conditions.

In our company, we use many innovative solutions not only in the field of computer-aided design, but also in the implementation of other services. We deal with, among others: CNC milling, CNC turning, grinding, welding, 3D scanning and locksmithing.

Karbo CNC experts have appropriate competences and constantly undergo advanced training. We approach each task creatively and boldly, treating all projects individually. We successfully complete even complex and complicated orders, while ensuring compliance with applicable standards. We also have appropriately equipped machinery. We invite you to contact us and check the Karbo CNC offer.