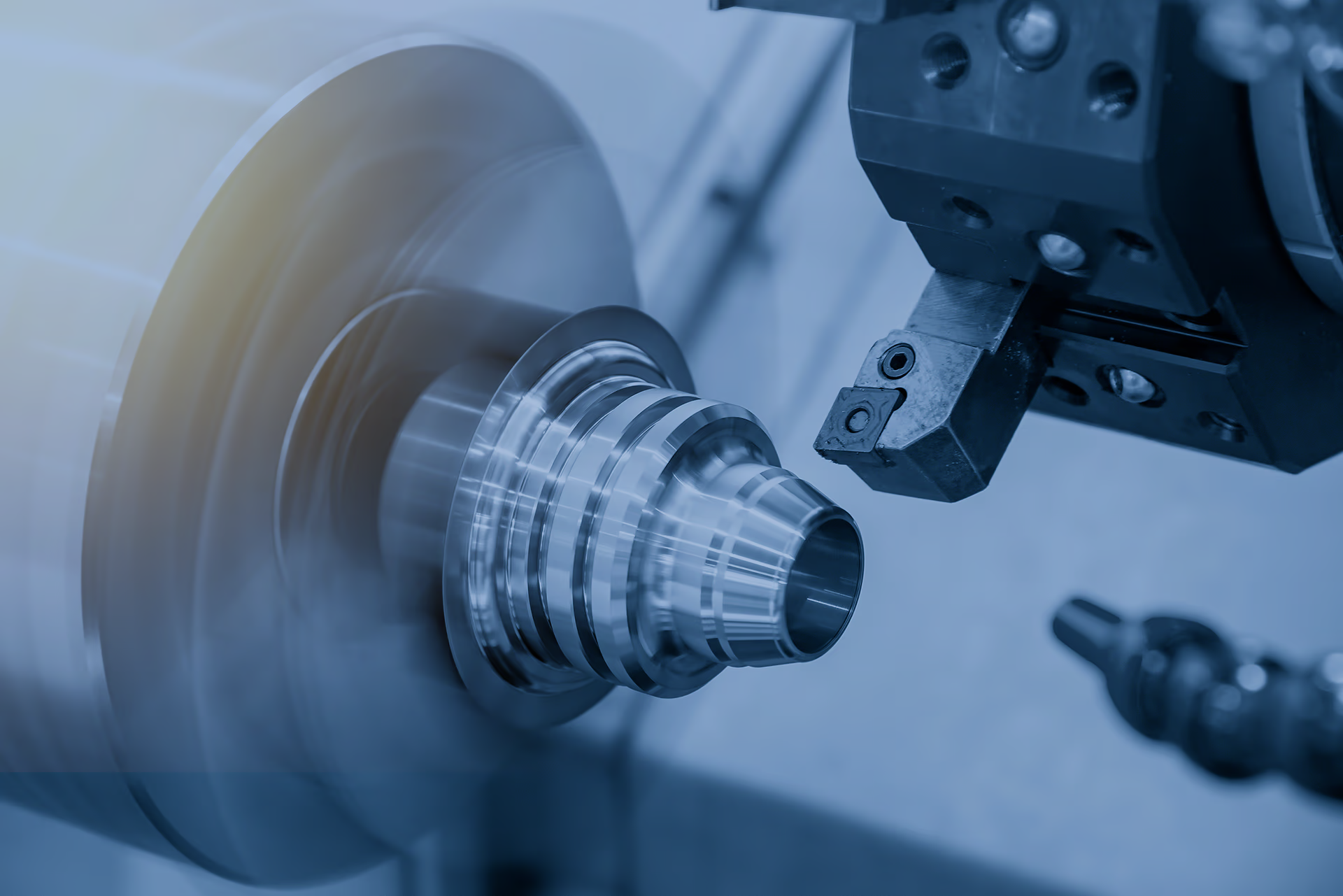

CNC turning is a proven and valued method of machining that allows the processing of material by removing its excess from a selected element. This technology enables the processing of internal and external surfaces of objects with specific geometric features.

In this process we use modern numerical control, which affects the speed, precision and repeatability of work. CNC allows for significant automation of many activities.

CNC turning is a service efficiently performed by our company’s specialists. At Karbo CNC, we provide comprehensive services in the field of machining using modern methods, ensuring the processing of materials in accordance with strict guidelines.

Our specialists guarantee high precision and accuracy, which affects the final quality of the products. In this process, we use computer control to control the tip of the machining tool relative to the workpiece. The CNC method allows for point, shape or envelope machining.

CNC turning is one of our most frequently chosen services, and there are many potential benefits associated with outsourcing it.

We provide services in this area for the needs of various industries, and our excellent market knowledge allows us to select optimal technological solutions for each business.

We are able to efficiently and effectively carry out CNC machining, the costs of which depend mainly on the specific nature of the processed material, the size of the order or the level of complexity of the project.

All work related to this machining method is performed in multiple stages, using appropriately selected lathe knives and CNC software.

Evaluate customer requirements, select appropriate processing methods and technologies, and develop a work plan.

Creation of technical and process documentation, and preparation of appropriate tools and selection of machinery.

Execution of the planned technological process, according to the guidelines and documentation.

Conduct quality control, based on the established quality assurance system.

In the turning process using this method, modern CNC machines are used, which differ significantly from standard machines. Their main advantage is the ability to computer control the tools used to process the material. The use of this technology is based on Computerized Numerical Control, implemented using appropriate software.

CNC machining is performed by launching a program based on special algorithms and functions, which is then implemented by the machine controller. In the turning process using this method, we can significantly reduce the operator’s participation due to the extremely quick configuration and automation of work. In our company, we use the latest CNC lathes with driven tools, and we approach each order comprehensively. We prepare the design and then carry out its production.

Turning using computer control allows the processing of various materials, including ordinary and non-ferrous metals, aluminum and plastics. The first stage involves programming the CNC machine and then placing the workpiece in the lathe, after which it is set in rotation. The movement of the turning tool allows the cutting of the workpiece layer, which is done in accordance with the established parameters. Computer control differs significantly from classic manual operation.

CNC lathes can precisely perform tasks based on strict commands, which reduces the need to manually set the cutter and correct further steps. The processing performed by our specialists is precise and repeatable, thanks to which the finished element always meets the customer’s strict requirements.

Our company is particularly committed to innovation in the industry. We constantly follow what’s new on the CNC market and try to implement them in our own activities. We have many years of experience in carrying out this and other processing methods, but we still approach each project individually and treat it as a unique order.

We provide services in accordance with current standards, which translates into high safety at every stage of the production process. We are happy to take on the biggest turning challenges, and our extensive machinery allows us to remain flexible and efficiently carry out small and large series. Please contact our experts and check out other Karbo CNC services.