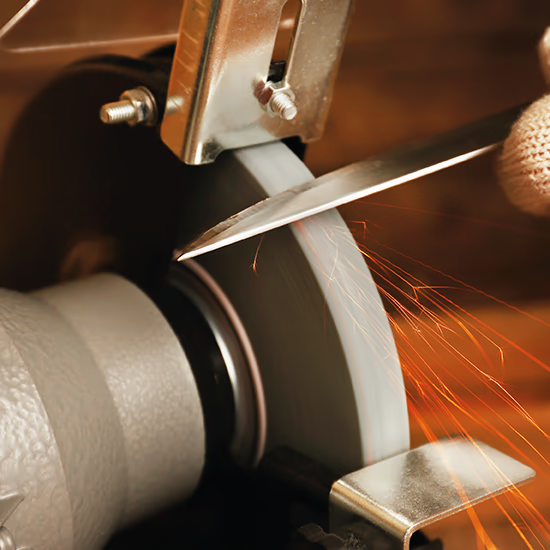

Grinding is one of the most commonly used techniques for processing metal materials, primarily steel and stainless steel. The purpose of grinding is to obtain appropriate roughness of the processed surface and precise dimensional accuracy.

This method has been used in many industries for years due to its unique advantages. It allows, among other things, to improve the mechanical properties and protection of details, increasing their strength and at the same time improving their aesthetic values. Effective extension of the life of surfaces treated in this way is also important.

Grinding is part of the services provided by the specialists of our company Karbo CNC. As a trusted business partner and industry leader in the mechanical processing market, we always strive to be comprehensively and professionally involved in each project.

We provide service using modern grinding tools, which translates into high quality processing. We grind ordinary steel and self-passive stainless steel, maintaining its anti-corrosion properties, which results from the use of appropriate tools and skillful implementation of abrasive processes.

Note: Grinding is grinding work performed using shaft and hole grinders or surface grinders. The grinding wheel is set in motion!

This is grinding with machines that give the appropriate smoothness

Grinding is a service that we can efficiently provide for many different projects.

Such processing must be carried out with great care and precision, because even small manufacturing errors increase the risk of material imperfections.

We encourage you to entrust us with this service, because at Karbo CNC we use methods that reduce the likelihood of damage, excessive roughness, potential corrosion or deposition of contaminants.

Our specialists also provide other professional services, including CNC milling and turning, CAD/CAM design, 3D scanning and welding.

We perform such machining using proven methods, which are based on the use of specialized grinding machines for shafts or holes and advanced surface grinding machines. Appropriate tools allow you to obtain the required surface smoothness as well as its desired dimensional accuracy. After the tool is put into rotation, the grinding wheel affects the workpiece at high speed.

In this way, the surface achieves an optimally low roughness, which results from high precision of finishing. Grinding machines used by our specialists enable effective processing of internal and external cylindrical surfaces, as well as planes. During operation, we effectively control all grinding wheel parameters, including grain size and hardness, which optimizes the entire process and minimizes the degree of tool wear.

At Karbo CNC, we use grinders with appropriate protections that protect the processed materials from overheating and maintain their structural integrity and physical properties. Due to the highest quality standards, the grinding offered by our company guarantees appropriate surface parameters in terms of mechanical properties and its strength.

We respond quickly to any irregularities, which translates into optimal repeatability, constant rotational speed, correct feed rate and correct cutting depth. Each processed element is carefully mounted in the grinder, which ensures the stability of the entire process. This solution guarantees effective elimination of vibrations, which reduces the risk of defects on the surface subjected to grinding. We individually select optimal technologies for the specificity of the project, thanks to which we provide personalized service.

The comprehensiveness of our offer is largely due to our service being focused on modern solutions. We constantly monitor innovations on the market, thanks to which we are able to provide services using the best technologies. Our specialists have extensive experience and their skills are successfully used in subsequent projects.

We approach each order individually and creatively, and we are not afraid of the most complicated and demanding challenges. At the same time, we ensure compliance of all processing stages with current standards, which has an impact on safety. Our company also has a constantly developed machine park. We encourage you to contact Karbo CNC and follow our offer.