The CNC machining blog is a place where we share a lot of interesting information about our services, the technologies and materials used, and the latest achievements in the industry. The presented articles constitute a unique and valuable source of knowledge and may also prove to be a very good way to obtain specialist advice. In the published content, we present many details related to professional processing, which is used in many market areas.

Why is it worth visiting our blog about CNC machining?

The blog about CNC machining run by our specialists focuses primarily on the most important factors regarding specialized methods of processing various materials, as well as other services offered by Karbo CNC. Thanks to it, you can learn a lot of useful information that will help you choose appropriate technologies and solutions at the stage of implementing specific projects. On the blog, we present numerous articles devoted to the specificity of specific machining operations, which allows us to obtain numerous recommendations regarding target applications and the use of specialized CNC methods in practice.

Comprehensive and specialized content

Our specialists stay up to date with various industry innovations, thanks to which all information presented on the blog is always up to date and properly verified. The content included in the articles allows you to make better investment decisions, which results from the possibility of choosing appropriate processing methods. Our experts also present many proposals for implementing CNC technology on specific examples that comply with applicable standards and safety requirements.

What is the focus of our CNC machining blog?

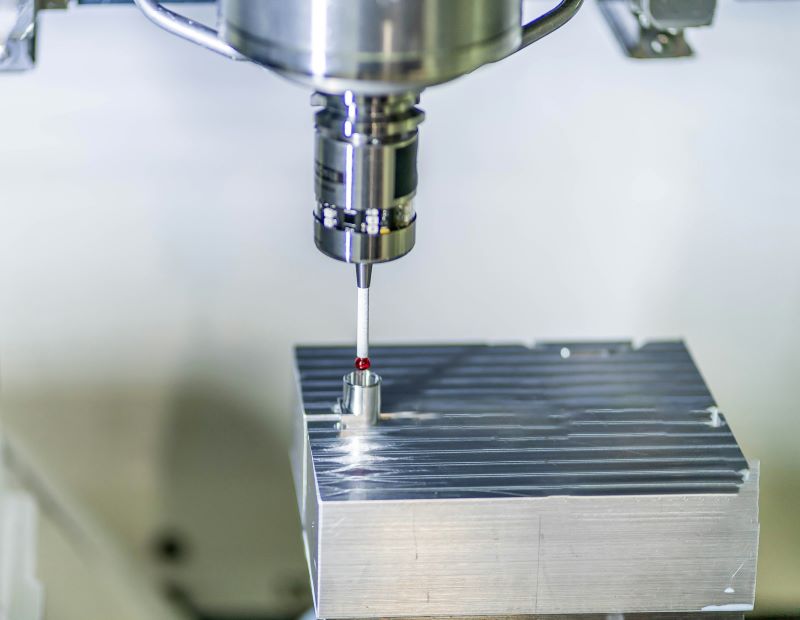

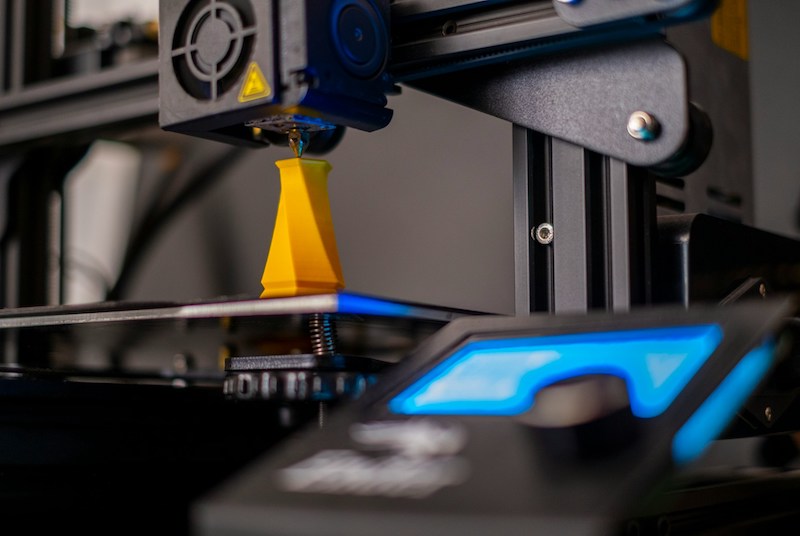

The CNC machining blog edited by our experts covers various topics related to metal processing and related services. At Karbo CNC, we successfully handle each order comprehensively, thanks to which we are able to efficiently present the details of this process to our readers. We deal with both the design preparation stage and the final production. On the blog we discuss topics including: CNC milling and turning, as well as welding, grinding, locksmithing, 3D scanning and CAD design.

Valuable and practical information

We present only reliable and useful information on the blog. We have gained knowledge in the field of CNC methods thanks to many years of experience in the industry, as well as due to special attention to compliance of each project with the highest quality standards. We successfully use advanced technological solutions and carry out complex tasks, which also translates into the comprehensive content of our articles. We are a proven partner that fully meets the needs of every investor in terms of business and beyond.

Substantive knowledge

We recommend our blog especially to investors who want to gain knowledge about various technologies or work methods. Thanks to our articles, you can better learn about processing procedures, which we always approach individually and take care to personalize all orders. We discuss individual elements of the equipment of our machinery, which allows for efficient execution of work even in the case of the most demanding and ambitious projects. Please contact Karbo CNC and read the articles posted on our blog.

18.06.2025

18.06.2025