01.10.2024

3D scanning is currently an increasingly popular method of designing various components and elements. This technology can significantly improve production processes and increase the level of their control, and at the same time improve the quality of finished products. Three-dimensional scanning services are also invaluable at the stage of performing various material tests. Their goal is to develop a 3D spatial scan of a specific object, which is then used in numerous processes.

What is 3D element scanning used for?

3D scanning of elements is one of the services offered by the specialists of our company Karbo CNC, where we carry out it for the implementation of many projects. We perform activities in this area using modern technologies that allow us to prepare scans with appropriate parameters. We can seamlessly combine the scanning service with the development of a three-dimensional CAD model, as well as the preparation of full technical documentation. Three-dimensional scanning is extremely useful in implementing numerous technological processes, such as part dimensioning, parameter comparison or collision control. The service is also useful in reverse engineering activities.

Versatile possibilities

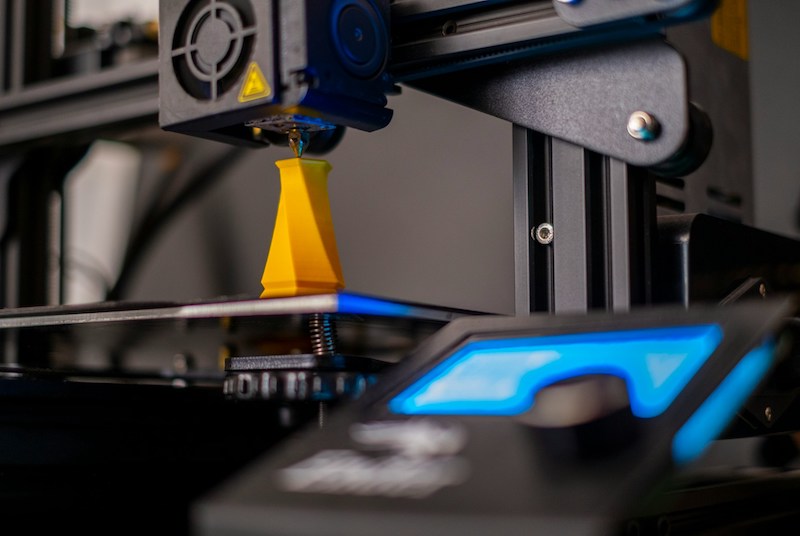

Currently, 3D scanners are widely used in many industries that produce specific end products. In our company, we approach all stages of the process comprehensively. We not only prepare a spatial scan, but also use it to create new product forms or model parts. This service allows for exceptionally precise reproduction of real object elements, which facilitates the development of ready-made CAD models. At later stages, we can also use 3D scanning to improve the final product. It successfully facilitates changing the thickness or inclination of an object, as well as its other properties. The three-dimensional scanning process allows easy measurement of the entire surface of the element, which improves the identification of potential product imperfections. This method significantly improves quality control and material testing because it shortens work time and lowers costs.

High operational efficiency

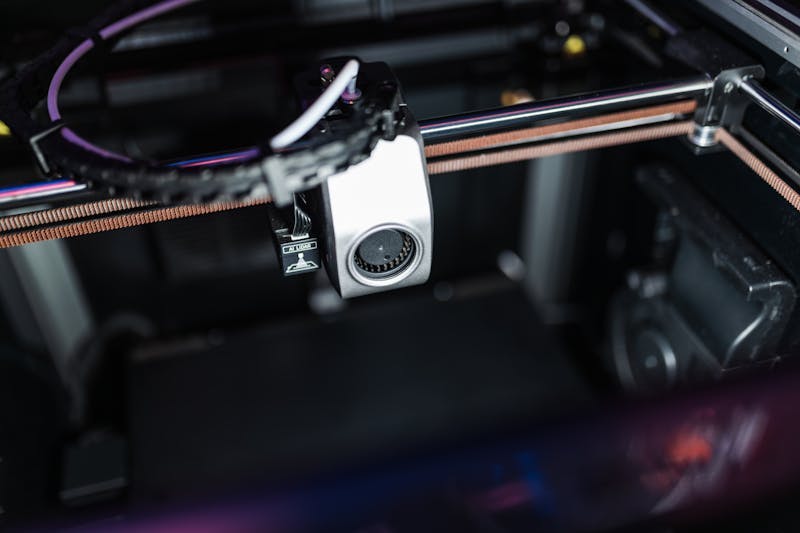

The three-dimensional scanning service is extremely universal, which results from its high efficiency. The devices and systems used for this purpose are very accurate and can cover numerous measurement areas. Additional improvements, such as the integrated photogrammetric system, are also worth mentioning. Modern 3D scanners can effectively reproduce even technologically very complex elements, including free surfaces or those with complex geometry. Karbo CNC experts have extensive experience in three-dimensional scanning and also have certified equipment at their disposal. Our company is equipped with professional software that allows us to efficiently compare actual and nominal data. We also provide investors with complete reports that include all information regarding the project.

What are the benefits of a professional 3D scanning service?

The 3D scanning service provided by specialists ensures that each task is performed with maximum care. The attention to precision of technical parameters results from the appropriate skills of our engineers and the availability of professional equipment. We guarantee high measurement accuracy as well as compliance with restrictive regulations and standards. We efficiently perform 3D scans of both small parts and large and highly complex structures. Our service can significantly improve the process of introducing new products to the market, as well as their modification or reconstruction.

Comprehensive offer

At Karbo CNC, we have a modern machine park as well as constantly developed technological resources. We use proven and effective scanning methods, thanks to which we meet the needs of various industries. Due to our great versatility, we also successfully provide other services. We specialize in professional machining activities, such as turning, milling and grinding using CNC technology. We also perform locksmith and welding work. We approach all orders with creativity and precision, and at the same time guarantee personalized and comprehensive service.

Specialized service

To ensure the best possible spatial scanning effect, we use proven technological solutions. We also keep up to date with all industry innovations to efficiently introduce them to our offer. At Karbo CNC, we conduct regular staff training, which translates into very high quality of service. We also perform all work in compliance with safety rules. We encourage you to check the current offer of our company, as well as contact us and ask any questions about individual services.

31.03.2025

31.03.2025