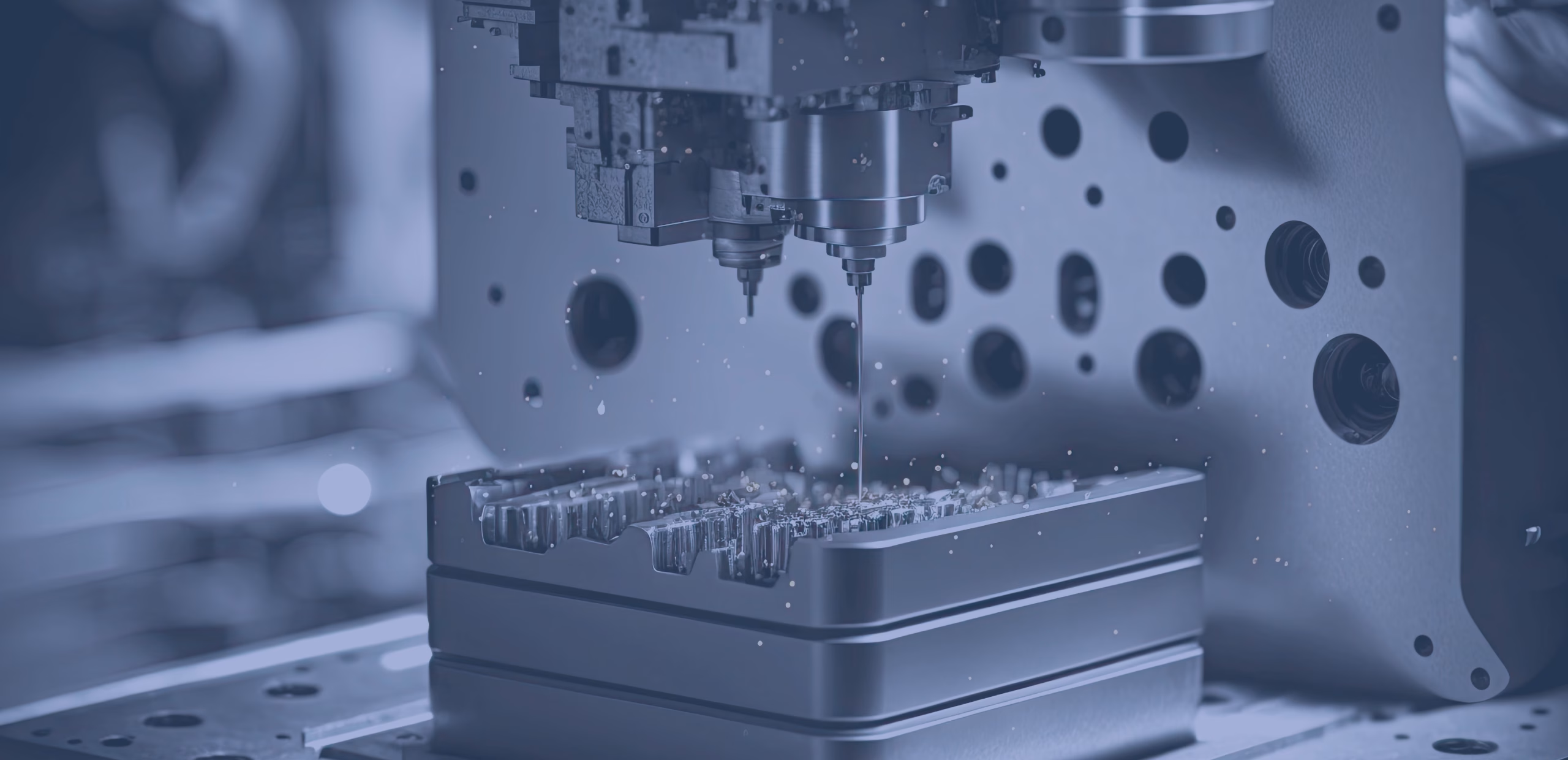

CNC milling is one of the most frequently performed machining services, which is performed using modern computer-controlled machines. It involves computer control of a cutting tool set in rotation relative to a permanently mounted workpiece. In this process, we can shape various materials appropriately, obtaining the desired parameters. Milling is a processing method that guarantees very high precision. It is also important that ready-made details can have virtually any form.

CNC milling is a service we offer at our company Karbo CNC. All activities are carried out by experienced and comprehensively trained specialists. Machining with this method involves appropriate preparation and immobilization of the selected element, and then its processing using a configured cutting tool.

In our company, we carry out milling for both small and large production series. This approach allows us to maintain high work flexibility and thus better adapt the service to the individual needs of our clients.

CNC machines used by our specialists are always properly programmed, thanks to which they can easily complete a certain number of repetitions and deliver the assumed number of finished parts. In this process, we use advanced computer software that allows us to develop a program that efficiently performs individual activities in accordance with the required commands.

This solution significantly improves and automates a number of technological processes, making it easier to select the appropriate revolutions, feeds and positions, and speeds up the clamping of the tool itself. CNC operation in this respect also guarantees high precision, thanks to which the finished elements have repeatable and closely matched technical specifications.

CNC milling is an extremely advanced and effective machining method, the choice of which offers a number of benefits.

We sincerely recommend entrusting this service to our specialists, because we are also able to perform it using the three-dimensional method to prepare spatial architectural, building and construction details.

This service is also very economical, and its costs depend mainly on the size and type of processed materials, the size of the order and the level of project complexity.

Evaluate customer requirements, select appropriate processing methods and technologies, and develop a work plan.

Creation of technical and process documentation, and preparation of appropriate tools and selection of machinery.

Execution of the planned technological process, according to the guidelines and documentation.

Conduct quality control, based on the established quality assurance system.

The processing methods used by our specialists allow for the processing of materials with high precision and also enable working on several planes at the same time. This type of CNC machining is perfect for creating a variety of components, molds and parts that are used in a number of industries. We successfully mill metals, aluminum, non-ferrous metals and plastics, ensuring that all activities are adapted to the specific nature of the project and the required technical parameters.

We give priority to the quality of details so that they fully meet the investor’s needs. CNC technologies used by our experts guarantee optimal dimensional tolerance. We also take a comprehensive approach to control and supervision, which is why we monitor the implementation of each process and maintain the desired properties of the treated surfaces.

At Karbo CNC, we are strongly committed to innovation, which is why we constantly identify new milling methods and use them in practice. Due to many years of industry experience, we are able to individually approach the specificity of individual orders and treat them as unique projects. Our specialists always comply with demanding standards and restrictions to ensure the safety of machining processes at every stage of production.

We provide detailed service even in the case of the most difficult orders, and we also approach complex and complicated projects creatively. We have a modern machine park and constantly develop our staff through comprehensive training. We encourage you to cooperate and contact Karbo CNC. As a trusted partner, we are always able to find optimal solutions for the needs of each business.