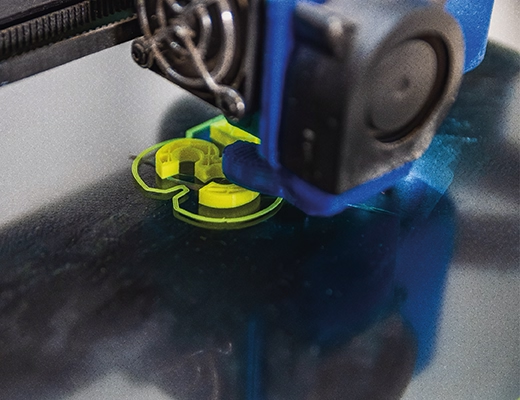

3D scanning is a service that is currently becoming more and more popular among many investors. This is a service that involves reproducing the shape of the received detail.

This technology significantly facilitates the design of new products and the control of production processes, and may also contribute to improving the quality of finished products. Activities in this area also prove effective in terms of increasing the efficiency of material research. The basic goal of the service is to prepare a three-dimensional, three-dimensional scan of the selected object.

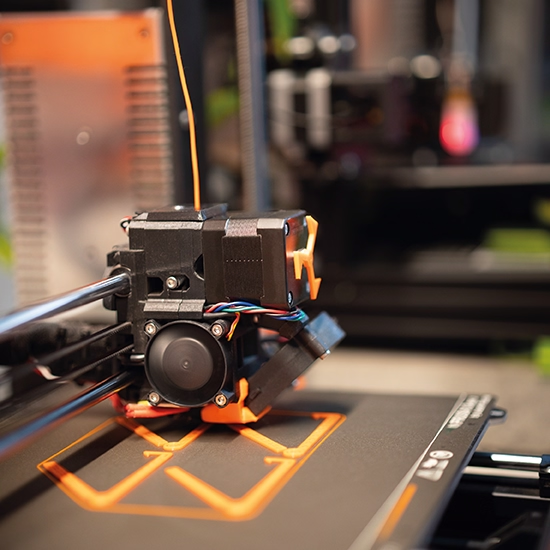

3D scanning is a service efficiently carried out in our company Karbo CNC, where we implement it for the needs of various technological projects. For this purpose, we use technologically advanced devices that allow us to perform precise measurements and scans of objects of various dimensions.

This service can be effectively combined with the preparation of a 3D CAD model as well as the preparation of complete technical documentation. 3D scanning is irreplaceable at the stage of comparing various parameters, dimensioning parts, checking collisions or conducting comprehensive activities for reverse engineering.

3D scanners are currently widely used at almost all stages of production of final products in the production process. At Karbo CNC, we carry out all work comprehensively, including preparing the scan and using it in modeling parts or developing new product forms. 3D scans allow for very faithful reproduction of various real elements, which allows the creation of CAD models and their optimization in terms of improvements to the final product.

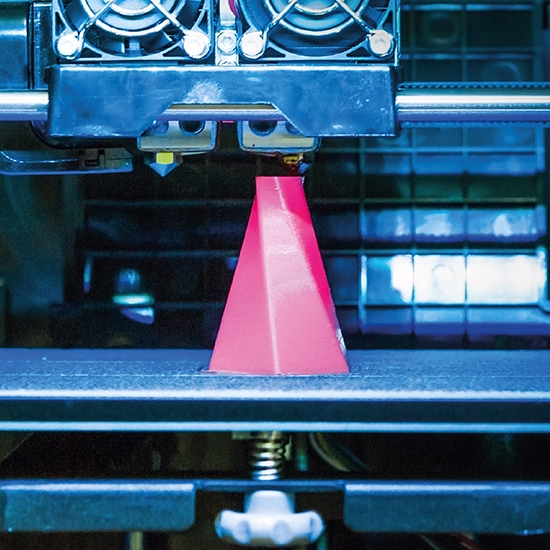

The service is useful, for example, when it is necessary to change the slope, thickness or other properties of an object. Three-dimensional scanning allows you to measure entire surfaces and thus detect potential defects in manufactured and processed products. Material testing and quality control carried out using this method are very effective, reducing costs and saving valuable time.

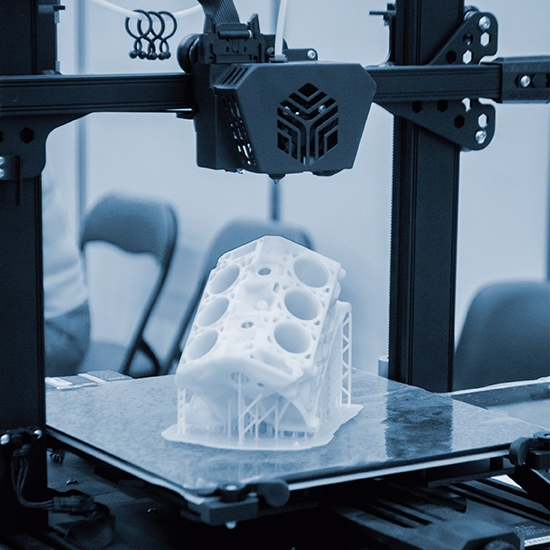

The 3D scanners used by our specialists are very universal, which results from their numerous utility advantages. Properly designed equipment is characterized by high accuracy, has several measurement areas and an integrated photogrammetric system. Advanced 3D scanners allow for trouble-free reconstruction of even the most complex elements, such as complex geometries or free-form surfaces.

Our company has extensive experience in preparing three-dimensional scans and also has certified measuring equipment. We are also equipped with advanced software that enables comparison of actual data with nominal data. We also prepare specialized reports according to customer requirements.

We always carry out 3D scanning with great attention to the accuracy of technical parameters, which is ensured by the appropriate qualifications of our engineers and the availability of certified equipment.

We successfully meet the highest standards in terms of measurement precision, while operating in accordance with applicable standards.

We are able to perform three-dimensional scans of both small elements and larger objects with varying degrees of complexity of geometry.

We also create complete documentation and help in the reconstruction, modification and introduction of various products to the market.

Evaluate customer requirements, select appropriate processing methods and technologies, and develop a work plan.

Creation of technical and process documentation, and preparation of appropriate tools and selection of machinery.

Execution of the planned technological process, according to the guidelines and documentation.

Conduct quality control, based on the established quality assurance system.

Extensive technological resources and extensive machinery allow us to provide comprehensive services. At Karbo CNC, we use advanced three-dimensional scanning methods that fully meet the modern requirements of many industries.

We have high-functional equipment, which translates into the ability to perform various 3D scans. Our company’s offer is very comprehensive and largely focuses on specialized engineering activities, including CNC milling and turning, grinding, welding, CAD design and locksmith processing. Our team approaches each order professionally, ensuring individual service for all projects.

The basis of our activity is customer satisfaction, which is why we always prepare 3D scans of the highest quality. The technologies and materials used by our specialists are based on proven solutions as well as many industry innovations. We constantly follow market news and constantly train our staff to ensure the highest quality of service.

We supervise and control all stages of work related to 3D scanning, which contributes to maintaining safety and guarantees investor satisfaction with the achieved effect. We invite you to contact the experts of our company Karbo CNC, and we also encourage you to take advantage of our specialized service offer.