27.11.2024

Machining of stainless steel is a technological process that currently has very versatile applications. This is largely due to the mechanical properties of the material itself. Stainless steel is resistant to corrosion and therefore extremely versatile. Modern machining methods allow it to be processed in such a way as to ensure high precision and at the same time minimize material losses. CNC technology is particularly popular.

What is the basis of machining of stainless steel?

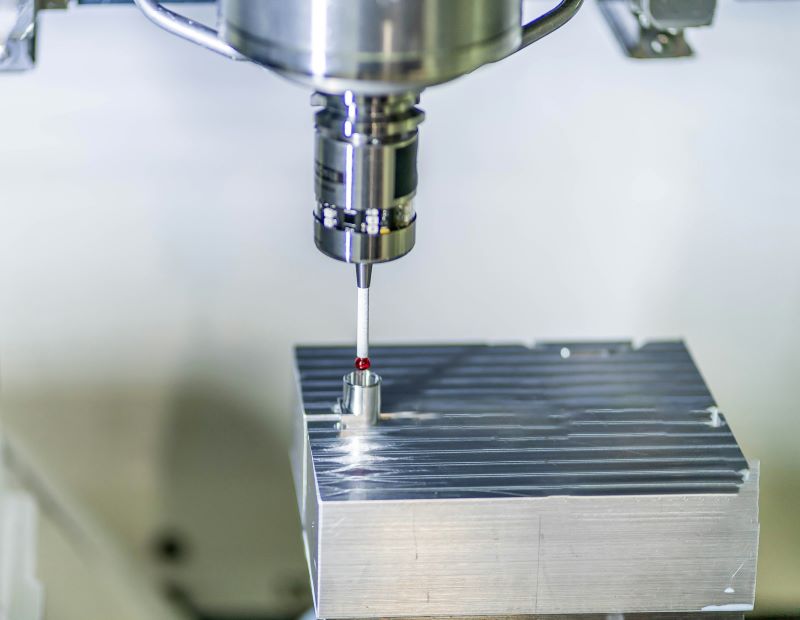

Machining of stainless steel is one of the services provided by our company Karbo CNC. We process this material using numerically controlled machines that implement a computer-programmed algorithm. We perform processing in various forms, including milling, grinding, turning and welding. Stainless steel has excellent corrosion resistance and low thermal conductivity, but is relatively demanding in shaping. For this reason, we take care of a comprehensive approach to the entire service, including project development, machine configuration and technological process development, while maintaining quality control guidelines.

Selection of appropriate tools

Due to its high strength and abrasion resistance, stainless steel requires processing with tools resistant to difficult working conditions. In providing our services, we use solutions that are resistant to high temperatures and can withstand significant loads. We have tools equipped with appropriate protective coatings that reduce friction and eliminate the risk of steel sticking. We are able to efficiently carry out even the most demanding operations, including machining of large batches of details. We also ensure proper optimization of the entire process, selecting the appropriate rotational speed, depth and feed to suit the specific material and all project requirements. We also use advanced cooling systems, which reduce the risk of thermal deformation and increase the tool life.

Application of CNC technology

In our company, we specialize in CNC machining, which is widely used in the processing of stainless steel. Computer-controlled machines can efficiently perform even the most complex tasks, while ensuring high precision and repeatability. The efficiency of the process is significantly influenced by the use of specialized CAD/CAM software, thanks to which we can perform each service even more efficiently. CNC technology helps minimize machining cycle time and also reduces energy consumption. Due to advanced algorithms monitoring the operation of machines, we can constantly control the quality, make necessary corrections and eliminate any possible irregularities.

What is the application of machining of stainless steel?

Machining of stainless steel is a service that is currently necessary in many areas of industry. The use of this material works well in areas requiring the highest quality, such as the automotive, electronics, aviation, pneumatic, energy and agricultural industries. Regardless of the specificity of the project, we can efficiently adapt the entire machining process to individual customer requirements. At Karbo CNC, we take on various challenges, including projects requiring a personalized approach. We also ensure high quality when providing other services, such as: scanning, 3D printing or comprehensive locksmith processing.

Main benefits of CNC technology

CNC technology provides many benefits, including high accuracy of each machining. In the case of stainless steel details, we are able to achieve maximum repeatability of parameters. Due to the automation of the entire process, we reduce the risk of errors and increase the quality of the finished product. The use of appropriate machines allows you to prepare many variants of the selected detail, which only requires modification of the settings and algorithm. The service we offer is very economical due to reduced production costs and shortened work time. Also noteworthy is safety, ensured by minimal contact of the operator with machining tools.

Comprehensive range of services

Our company provides comprehensive services related to the shaping and processing of stainless steel. We can process it in various forms. We offer, for example, CNC turning, which allows for point, shape or envelope machining, which significantly increases the range of possibilities. To provide this service, we use control to control the tip of the machining tool relative to the workpiece. We also provide CNC milling for both small and large production series. We encourage you to contact our experts and check the comprehensive Karbo CNC offer. We are distinguished by high work flexibility, which allows us to better tailor our service to potential customers.

18.06.2025

18.06.2025