At Karbo CNC, we offer a full range of CNC machining services, starting from the design stage and ending with final production. The course of a properly developed technological process is carried out under control supervision. Thanks to advanced technologies and many years of experience, we provide comprehensive services that include CNC turning, CNC milling, grinding, CAD design, 3D scanning, welding and locksmith processing.

We have the latest CNC machines, which allows for precise processing of even the most complex elements. Possibility of simultaneous machining in 5 axes.

Our employees are qualified specialists with many years of experience in the industry, ensuring the highest quality of workmanship.

Thanks to our diverse machinery, we are able to carry out both small and large production series, adapting to customer needs.

We constantly invest in technology development and staff training, which allows us to maintain a very high level in the technological development of the company.

Each product undergoes rigorous quality tests that ensure that all products meet the highest standards.

Mainly details for fuel apparatus and brake systems

Spare parts for machinery

Spare parts for machinery

Spare parts for machinery

Spare parts

Details according to customer order

Karbo CNC – precision and professionalism in CNC machining. We are a company that puts quality, accuracy and customer satisfaction first. Our services are the result of a combination of advanced technologies with a deep understanding of market needs.

Read More

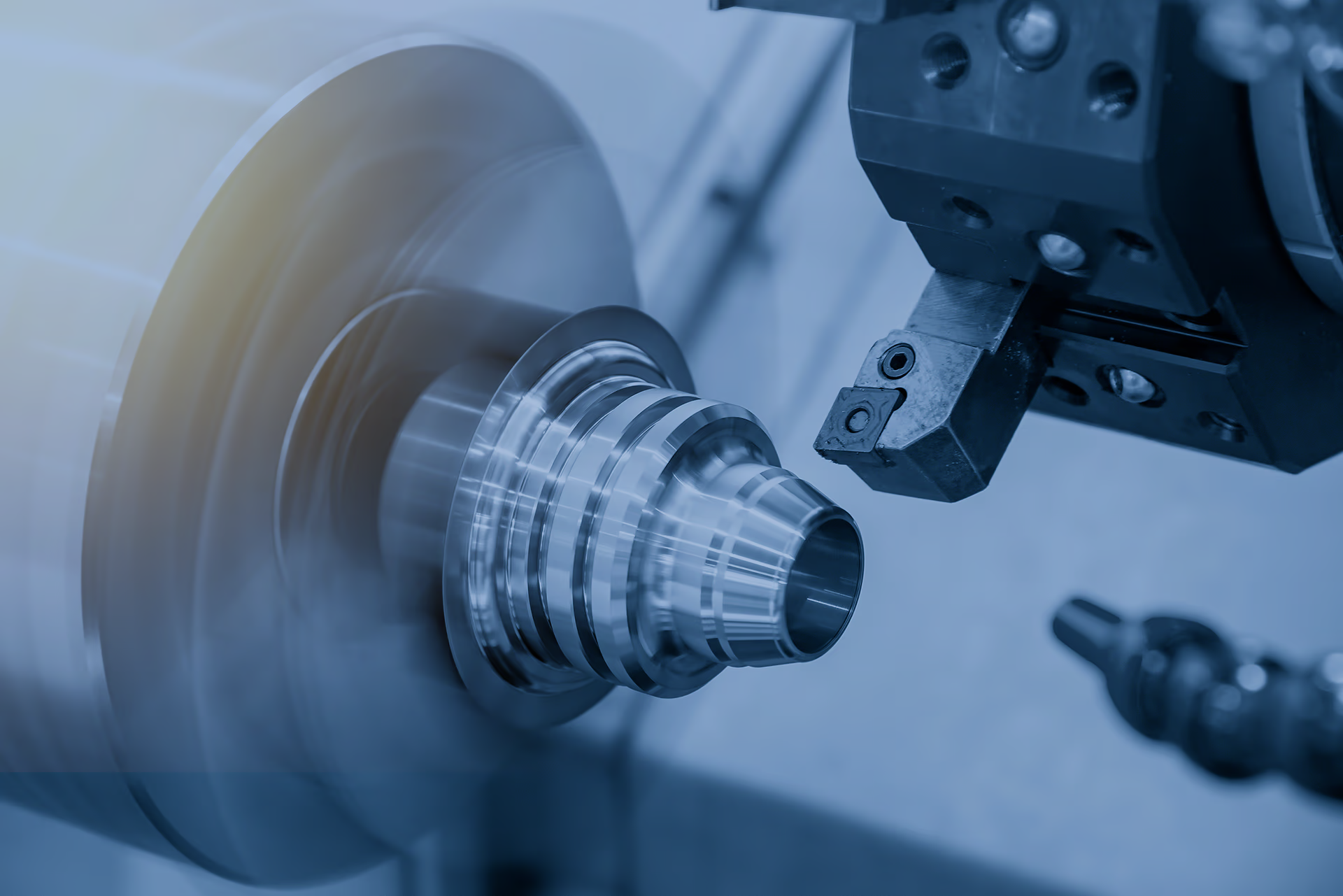

Turning services focus on the efficient machining of a wide range of materials. This technique allows for the processing of internal and external surfaces of components with diverse geometries. Currently, such services can be performed using modern CNC lathes, which are numerically controlled machines. Their use automates the operation of the turning tool and increases machining precision, repeatability, and rapid turnaround times, which are crucial in the production processes of various components.

Read More

Metal machining is an exceptionally precise processing method that finds applications in numerous industries and beyond. Currently, the implementation of this type of service has been significantly improved thanks to its reliance on innovative technologies. One such technology is the use of numerically controlled (CNC) machines. Such machining allows for the rapid, automated, and repeatable shaping of components and details, which is crucial for many projects.

Read MoreComprehensive CNC machining is perfect for shaping various materials for the needs of numerous industries. Technologies in the field of Computerized Numerical Control allow for the automation of a number of activities related to the machining process, which is carried out by computer control of the tool in relation to the workpieces. Based on an appropriate program, we carry out individual stages of work, while guaranteeing the desired quality of finished details.

Comprehensive CNC machining is the basis of the activity of our company Karbo CNC, where we provide many services related to the processing and shaping of various materials. We fulfill orders to the full extent, starting from project preparation and ending with final production. Our experts use advanced technological solutions and have extensive experience, which allows them to provide specialized service when creating any project. We offer, among others: CNC turning, CNC milling, grinding, as well as 3D scanning, CAD design, welding and locksmithing.

At Karbo CNC, we start our work by preparing a project that is created using appropriate software for creating element models and is prepared on the basis of a detailed specification and planning of the technological process. Based on drawing documentation or a model, we generate a program that we export to a format read by modern machines used for machining. The element subjected to CNC processes must be properly prepared and mounted, and then the tooling is configured. A properly set-up machine can efficiently execute set instructions. Machining is performed by performing specific movements of the tool tip relative to the workpiece, controlled by a specially prepared program. The CNC method guarantees obtaining a high-quality detail that meets the specification.

In our company, we pay particular attention to precision and customer satisfaction. Not only do we use advanced technologies in machining work, but we also perfectly understand the requirements of the modern market. We offer efficient and reliable solutions for the processing of various materials, such as metals, non-ferrous metals, aluminum and plastics. We are constantly engaged in innovation and follow the latest trends to constantly implement new working methods in our practice. We have many years of experience in the industry, which has an impact on the final quality of the products. We approach all orders individually, so we treat each project as unique and requiring appropriate service. We always apply rigorous quality control standards at individual stages of production. We successfully undertake even the most difficult and ambitious projects.

Comprehensive CNC machining carried out by our company is a complex technological process that is always carried out under the strict supervision of the best experts. We carry out the work with great precision, thanks to which every detail successfully meets the highest quality standards and design requirements. The use of appropriate technologies gives us the ability to carry out even the most complex tasks. Karbo CNC is a trusted partner that successfully meets a number of specific needs of every business.

There are many benefits associated with this type of processing. The services provided by our specialists are performed with great care, which allows us to obtain elements with the desired and repeatable features. The computer control process significantly reduces the risk of operator errors, thanks to which there are no imperfections in the final products. CNC machining also gives us the opportunity to prepare many versions of one element, which is done by quickly modifying program settings. The technology used by our company is also very profitable because it is associated with low operating costs and shortened production time. Its advantages also include high work safety. Automation of machining processes reduces production costs and limits contact with machines, which reduces the risk of accidents at work.

Our company has a modern machine park that enables multi-stage CNC machining of even highly complex elements. We are able to carry out simultaneous machining in 5 axes. We have an experienced team of qualified experts who have been operating in the industry for years. At the same time, we ensure high production flexibility. Extensive equipment allows us to carry out small and large production series, thanks to which we can efficiently adapt to the investor’s needs. We constantly train our staff and introduce new solutions to maintain the company’s technological development at the highest level. We encourage you to check the current Karbo CNC offer and contact us.