18.01.2024

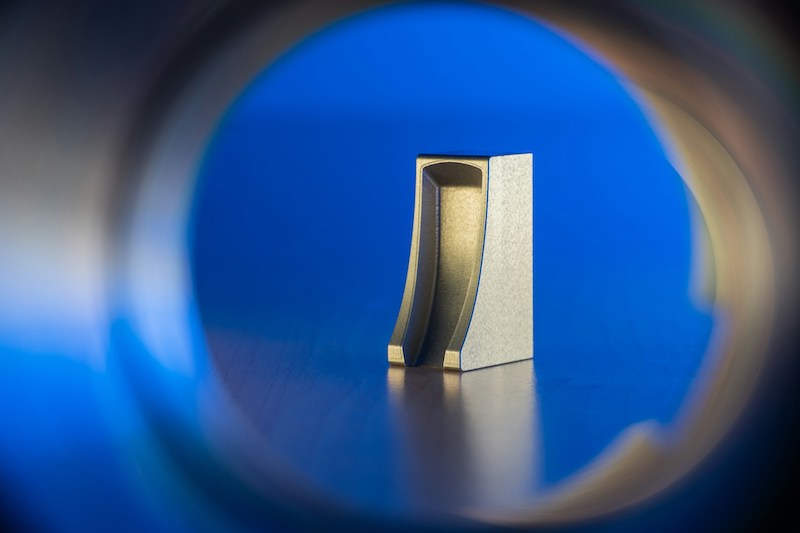

Metal processing is a process that is an integral part of the functioning of modern industry. The condition for high quality and precision of such services is their professional implementation, which requires the use of innovative technologies and the provision of specialized implementation services. Currently, a significant part of machining processes can be automated, thanks to which individual methods guarantee the desired accuracy and repeatability and offer exceptionally wide possibilities for shaping metals.

What possibilities does precision metal machining using CNC technology offer?

Precise metal machining is a set of technological activities in which our company Karbo CNC specializes. As an industry leader, we provide exceptionally diverse services, while meeting the expectations and requirements of clients from many industries. The basis of our offer is milling and turning, as well as grinding of details in accordance with precise guidelines. We also deal with CAD/CAM design, grinding, 3D scanning and welding services. We process steel, stainless steel and aluminum, as well as bronze, brass, fiberglass, plastics and other colored materials.

Advantages

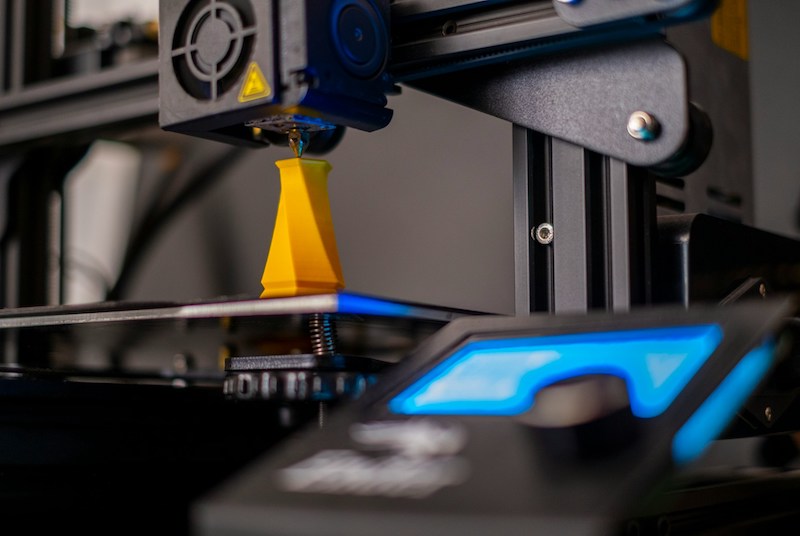

CNC methods used by our experts provide wide possibilities of shaping materials with high precision and repeatability of parameters. Computer control technology eliminates potential manufacturing errors, which has an impact on the quality of the final details. CNC machining also allows us to produce components in various versions, which only requires modification of program settings. The solutions we propose are also extremely economical because they contribute to shortening production time and reducing costs. A major advantage of CNC is also high work safety, ensured by limited contact with equipment and reduced likelihood of accidents while performing tasks.

Adaptation to many industries

We successfully provide our services to the needs of numerous industries. We serve the automotive and automotive segment in terms of the production of car, engine and gearbox parts, and we also support the pneumatics and machinery industry in the supply of machine elements, devices and tools. We have a wide range of products for the medical and pharmaceutical industries, including components for surgical tools, prostheses and implants. We also develop parts for pumps, radiators, housings, turbines and other products for the energy and electronics segments. We operate in the aviation, agricultural, chemical, petrochemical, metallurgical, electrical, rubber, wood and textile segments.

Why is mechanical and surface processing of non-ferrous metals with our company a good solution?

Mechanical and surface processing of non-ferrous metals should always be performed by a team of experienced experts who have good knowledge of modern technological solutions. A creative and bold approach to implementing various projects is also important. In our company, you can count on comprehensive, timely service for each task. We prepare projects and efficiently implement them and obtain a finished final product.

Comprehensive services and specialized service

Due to the extremely diverse range of available techniques, we are able to provide services optimally tailored to current market requirements. We use innovative CNC machines, which contributes to improving the quality, precision and speed of work. We ensure appropriate optimization of production processes, making them exceptionally effective and efficient. We meet the agreed deadlines, fully meeting the expectations of all customers. Our service is comprehensive because we provide it at every stage of project implementation. As a team of experts, we are happy to take on demanding tasks and propose many creative solutions. We provide an individual and professional approach to cooperation.

Highest quality and precision

At Karbo CNC, we give priority to the quality of each service, which has an impact on the satisfaction of our customers. The technologies used by our experts ensure wide dimensional tolerance and high accuracy, thanks to which they successfully meet the most demanding guidelines. We also try to constantly monitor and optimize individual production processes, and thus constantly improve the final finishing effect of the planned details. Cooperation with Karbo CNC ensures that a number of requirements of the modern industry are met. We encourage you to contact us by phone or e-mail and read the details of the services we offer.

31.03.2025

31.03.2025